If you have a question regarding what an isolation valve is,” You aren’t the only one with such a concern. Isolation valves provide integral functionality, particularly concerning the fluid control systems, since they offer the means for the efficient regulation of the fluids’ flow. In the course of this article, you’ll have an insight into isolation valves, their types, materials, purposes, industries that apply them, differences between them and gate valves, etc.

Understanding Isolation Valves

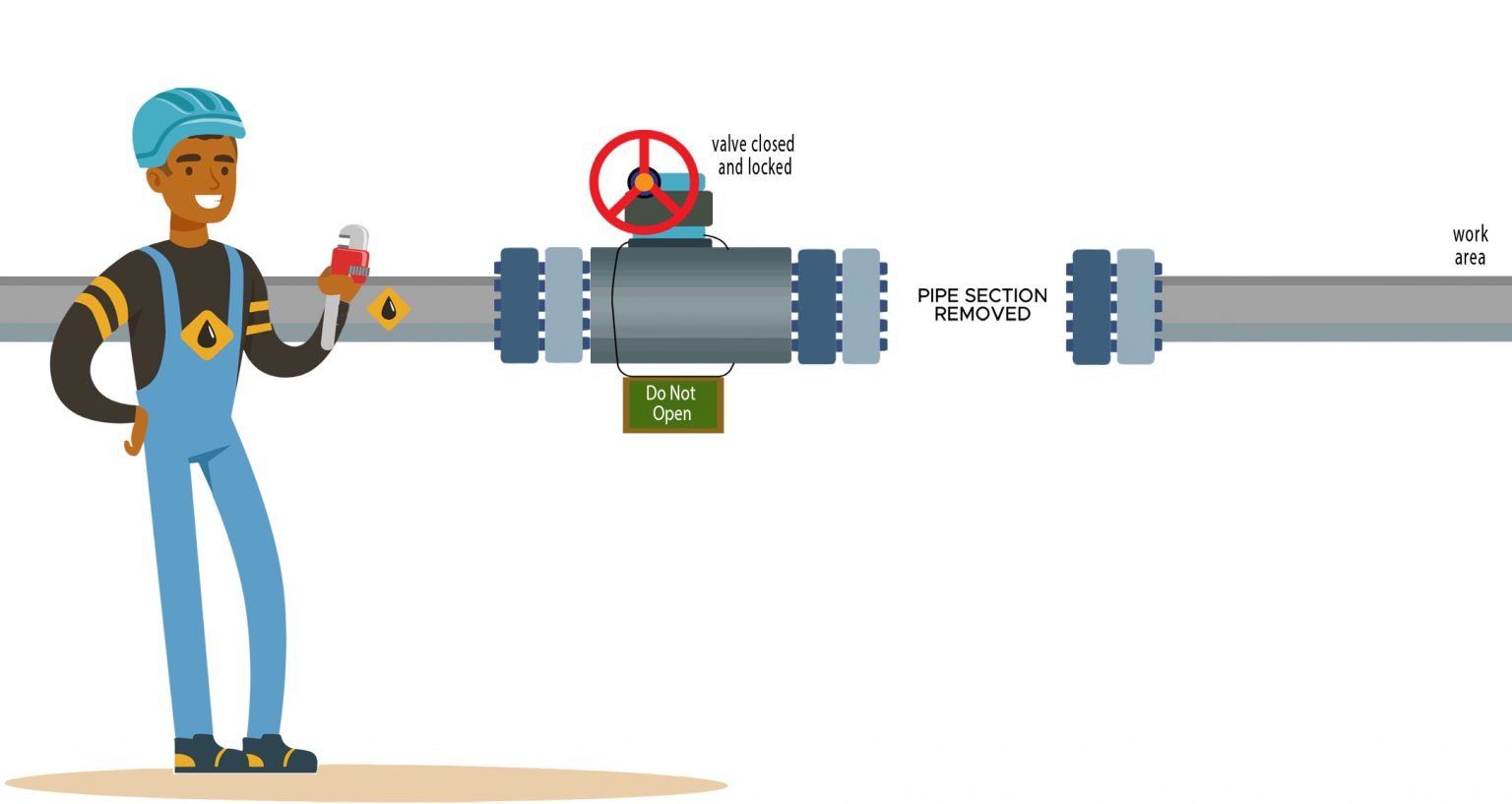

An isolation valve is a type of valve that is used with the purpose of shutting off a pipeline of a fluid, either liquid or gas. These valves are used in maintenance and safety as well as the operation of systems in several sectors like plumbing, oil, and gas industries. This process involves using a lock to shut off an IS in a given segment of the pipeline and work on it without interference from the rest of the facility’s pipes.

What Are Isolation Valves Used For?

Isolation valves are used in any number of applications where fluid flow control is required. Some of the most popular uses are:

- Turning off water supply during plumbing servicing

- Dividing sections of the pipeline within industrial systems

- Providing safety to pipeline measures and emergencies

- Allowing equipment maintenance without stopping the whole system.

- These adaptable valves are more necessary in areas with the manufacturing, healthcare, and energy production sectors.

Types of Isolation Valves

There are several varieties of isolation valves for a variety of applications and uses. Below are some of the types:

Ball Valves: Made of a spherical ball to manage movement and is famous for its toughness and dependability.

Gate Valves: Preferred in large pipelines, gate valves have full flow applications to give more confidence in resistance.

Butterfly valves: Lightweight and compact, which are used in process plants with space restrictions.

Globe Valves: These are utilized in throttling conditions to refine flow control.

What Are Isolation Valves Made Of?

Isolation valves are manufactured from different materials, to suit the application and the service in which they are used. Common materials include:

Brass: Ideal for water systems due to its corrosion resistance.

Stainless Steel: Suitable for high-pressure and high-temperature applications.

PVC: Lightweight and cost-effective for non-corrosive liquids.

Cast Iron: Rugged and running in heavy-duty commercial systems.

Isolation Valve vs. Gate Valve

It’s common to confuse isolation valves with gate valves, but they serve slightly different purposes. While both can stop fluid flow, isolation valves are often multi-purpose and can include ball, butterfly, or globe valves. Gate valves, on the other hand, are specifically designed to fully open or close a pipeline and are less effective for throttling or partial flow control.

How to Identify Isolation Valve Symbols

In technical diagrams, isolation valves are typically represented by specific symbols. The most common symbol resembles a circle with a diagonal slash through it. Understanding these symbols is crucial for reading pipeline schematics and ensuring proper installation and maintenance.

Industry Applications of Isolation Valves

Isolation valves are used across a wide range of industries, including:

- Oil and Gas: Ensuring safe shutdowns and flow control in hazardous environments.

- Pharmaceuticals: Maintaining sterile conditions by isolating specific sections of the system.

- Water Treatment: Controlling the flow of water during treatment and distribution.

- HVAC Systems: Managing heating and cooling systems for energy efficiency.

Below is a list of commonly asked questions about isolation valves:

Can isolation valves be automated? Yes, it is possible to specify many isolation valves with actuators for remote or fully automatic operation.

How often are isolation valves to be maintained? Routine scheduled maintenance to follow will depend upon the system’s operating conditions and environment, but annual inspections should be performed.

Are isolation valves compatible for high pressure? Some types, for example, ball valves and stainless steel valves, are suitable for high-pressure service.

Emerging Trends in Isolation Valve Technology

The valve industry is going through various developments due to technological advancements. Some emerging trends include:

Smart Valves: Embedding of IoT sensors for in-line real-time monitoring and control.

Eco-Friendly Materials: Creation of materials that decrease environmental effects.

Increased Durability: Pottery and seals for a longer life cycle.

Learn More About Isolation Valves

Now that you know the answer to “What is an isolation valve?” and understand its uses, types, and benefits, it’s time to explore how these valves can improve your fluid control systems. For more in-depth information, check out our comprehensive valve guide. You can also visit Valve Magazine for industry insights and updates.

Ready to enhance your system’s efficiency? Contact us today to learn more about isolation valves or to get expert advice on choosing the right valve for your needs.