If you are perplexed in knowing what a knife gate valve is, then you are at the correct place. Knife gate valves are used to control abrasive and other difficult materials such as slurry, thick fluids, and crystallized solids. In this article, what a knife gate valve is used for, the many specifications of a knife gate valve, and how it is different from several types of valves, such as the ball and gate valve, will be discussed. At the end of this article, you’ll be in a position to select the valve for your system and know the manufacturers to approach.

What Is a Knife Gate Valve Used For?

As for other materials, knife gate valves can be made of the most demanding materials in the industry. Due to their features such as sharp edge, they effortlessly slice through solids and are advisable in fields where standard valves cannot work.

Here are some common uses of knife gate valves:

Mining Industry: handling and dealing with slurries and abrasives.

Pulp and Paper Industry: Handling fibrous media like pulp efficiently.

Wastewater Treatment: Managing sludge and particularly the solid constituents in the wastewater stream.

Chemical Processing: Managing corrosive and viscous fluids.

Such valves are suitable for use in areas where standard valves like gate valves or ball valves are unsuitable to operate because of clogging or wearing obstacles.

How Does a Knife Gate Valve Work?

The strategy of using a knife gate valve is easy, although the outcome is usually very powerful. It consists of a flat type of gate with sharp edges perpendicular to the flow of the material in the system. Here’s how it works:

Opening: The gate recedes in the valve body, hence giving way to the flow of material through the valve.

Closing: The gate, made of a dense material, comes down with speed and descends into the seat, which sawn off all materials where it was installed.

This results into a built-in sealing system that will not allow any space for escape of the abrasive or solid laden material, making this option one of the best in industrial systems.

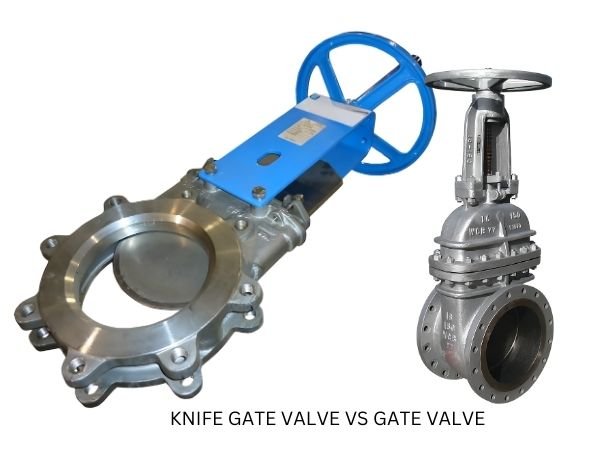

Knife Valve vs. Gate Valve

If one must compare the knife gate valve to the more conventional gate valve, then it will be important to understand the two as well as where to use them.

| Feature | Knife Gate Valve | Traditional Gate Valve |

|---|---|---|

| Design | Thin, sharp-edged gate | Thicker, wedge-shaped gate |

| Application | Slurry, solids, and viscous fluids | Clean liquids and gases |

| Maintenance | Easier to maintain in harsh media | Prone to clogging in tough conditions |

| Seal | Effective even with solids | Limited performance with solids |

Knife gate valves provide excellent sealing to cutting through high thickness materials while normal gate values are suitable for use on clean fluids and gases.

For more information with regard to gate valves and their types and specifications, the reader can visit the website of RUFSupply with a dedicated page for gate valves.

Types of Knife Gate Valves

There are two major categories of knife gate valves, namely, the following forms the most usual types:

Lug-Style Knife Gate Valves: These are used in various systems since they can be easily disassembled and maintained when needed.

Knife gate valves are available in wafer and lug styles. Other features include being extra mindful of space and light, thus suitable for installation.

Bi-Directional Knife Gate Valves: It means that this type of valve offers the capacity to block in both ways of flow.

High-performance knife gate valves: This kind of valve is particularly suited for applications that involve features such as high pressure or the use of corrosive materials.

Therefore, the selection of the type depends on the system characteristics based on the type of media it has to handle as well as the operating conditions.

Knife Gate Valve Specifications

When specifying a knife gate valve, it is important to consider certain factors that define its characteristics to get better results from the valve used.

According to the material of the valve body, it is further divided into carbon steel, stainless steel, cast iron, and ductile iron. Stainless steel is one of the best materials for use in a corrosive environment.

Size: It ranges from the small-diameter pipes, which are used in residential areas, to the large ones that are used in industrial estates.

Working pressure: They should be capable of withstanding the pressure that is prevalent in your system.

Temperature Range: Evaluate the valve’s ability to withstand temperature extremes in your system.

Understanding this will assist you in selecting a valve that will satisfy the required specifications.

Knife Gate Valve With Pneumatic Actuator

Pneumatic actuators are among the most common designs in operating knife gate valves. These actuators employ the use of compressed air with regard to the operational procedure of the gate so that the process can be more efficient in the fastest way possible.

Pneumatic actuators are ideal for:

- Systems requiring frequent valve operation.

- Remote or automated control environments.

- In the contexts in which a high-speed operation is desired.

For industries that need more accuracy as well as automated operation, there is also a possibility to look through the offers of instrument valves, such as needle valves or manifold valves.

Other Actuator Options

However, there are other types of actuators; the common one is the pneumatic actuator.

Manual Actuators: These are actuated by a handwheel and these are relatively cheaper and ideal for low pressure system.

Electrical: Usually adopts accurate control and is most often used in automatic handling of equipment.

Hydraulic Actuators: Designed for high-force applications, such as heavy-duty industrial processes.

The choice of the actuator you should make depends on your system type and the level of automation required.

Key Knife Gate Valve Parts

So, it is required to have a look at the knife gate valve and its main parts in order to better explain how it operates.

Body: The outer structure of the cavity, where the most important internal components of the valve are to be found.

Gate: The part of a gate involved in the process of cutting material.

Seat: Finishes off closure to make it rigid to open or permit the passage of fluids in the opposite direction.

Stem: it is used to link the gate to the actuator or manual handle.

Sealing: This is used around the stem to prevent leakage, while the handle aids in pushing the stem with ease.

All these parts have specific functions that make up the valve and its efficiency and effectiveness.

Benefits of Knife Gate Valves

There are several benefits of knife gate valves. Therefore, they are closing valued in different sectors:

Cost-Effective: More affordable than other heavy-duty valves.

Durable: Designed to withstand abrasive and corrosive environments.

Low Maintenance: Some of them do not require complicated structures, and hence, this means they do not require regular maintenance.

Flexibility: Can be used in many other applications such as mining or water and wastewater treatment, among others.

These advantages make knife gate valves reliable and efficient valves for problematic work conditions.

Maintenance Tips for Knife Gate Valves

The following are the steps to consider on how to maintain your knife gate valve effectively:

One important process is inspecting the gate and seat to tighten parties and identify any debris, wear and tear, etc.

Reduce Friction: By lubricating the moving parts, you are in a position to reduce the friction on the valve, and its operational lifespan increases.

Reverse rotation: When it is needed, reverse the flow of fluid to prevent buildup of deposits and other particles.

Worn Component Replacement: They should be replaced as soon as possible to avert interruption of services.

Maintenance is not only going to increase the durability of your valve but also at the same time also increase the efficiency of the same.

If you’re looking for high-quality valves for your industrial system, consider exploring options like ball valves or trunnion ball valve on RUFSupply. They offer a wide range of reliable products for various applications.

For additional insights into valve systems, you can also visit external resources like the Valve Manufacturers Association of America to learn more about industry standards and best practices.

Understanding what is a knife gate valve and its applications is essential for optimizing your industrial processes. Whether you need a valve for slurry, viscous fluids, or solids, a knife gate valve provides the perfect solution.

Ready to explore other valve types? Check out our complete guide to ball valves for a detailed look at their uses and specifications. Don’t miss out on finding the best valve for your system today!