Valve maintenance is the most effective practice that any organization in this world can adopt to maintain its system. In any application ranging from industrial pipelines and water systems to HVAC setup, it is paramount to ensure that valves are well maintained to avoid future replacements, probably during the most unfortunate time when they are needed most. Inadequate valve operation can, therefore, cause problems with your performance, which might bring a lot of trouble to your operations.

Here you will find the general information about the valve maintenance, the ways of installation of gate valve, the measures to prevent the problem, and the recommendations that correspond to your situation. Further, there is information about how such supplies as RUFSupply trunnion ball valves can improve the stability of your system.

Gate Valve Installation: Position and Procedure

1. Understanding the Correct Gate Valve Installation Position

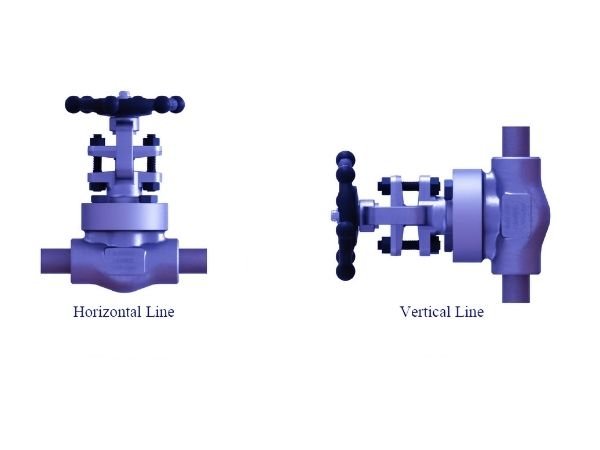

The gate valve installation position is critical to ensuring the valve functions correctly over time. You should always ensure that the installation position of gate valves is well chosen, especially for the purpose of regular maintenance checks. The horizontal installation is considered to be the most suitable, so that dust accumulations do not form, and movement is carried out easily.

You also should never install your valve in unfavorable conditions, for instance, where there is high temperatures, corrosive substances or a lot of vibrations. It is for these reasons that wear and tear of the valve is hastened which in turn shortens the expected lifespan of the valve.

2. Step-by-Step Gate Valve Installation Procedure

Following a proper gate valve installation procedure ensures your valve is installed correctly and performs at its best. Here’s what you need to do:

Before installation, the outside of the valve should be checked for dirt or other signs of wear.

Ensure that there are no foreign matters such as dirt or particles which may hinder the control of the valve.

Simply turn the valve so the arrow facing the body of the valve points in the direction in which the water is flowing.

After that, it is necessary to fasten the valve with nuts and bolts; however, it is necessary to pay attention and not tighten them too strongly so that they do not become broken.

Here are few more detailed views on the RUFSupply’s trunnion ball valves if you are searching for the valves that offer both endurance and effectiveness. These are intended for high-performance systems and come with high reliability in such conditions.

Building a Comprehensive Valve Maintenance Checklist

Therefore, having detailed valves maintenance checklist will facilitate the easy inspection and maintenance of the valves as follows; Here is how one can operate systematically to avoid leaving something out:

Examining the valve body, the inspector should be able to look for crack, corrosion, and leakage signs.

Examine seals and gaskets and replace them in case of wear.

To check its functionality, the valve should be opened and closed to its full range or fully closed until it properly opens.

Lubricate all parts that move relative to each other to ensure that they do not stick, and in case they are exposed to air, they do not rust.

This may involve the use of solvents, special clean rags, or brushing/plunging in order to dislodge the dirt blockage inside the valve body.

Valve Maintenance Checklist

By observing this checklist often, one will not fall victim to a fresh breakdown in their car. For additional detail about other maintenance tips, you can visit theengineeringtoolbox.com that provides excellent and reliable information on all system optimization.

Preventive Maintenance Strategies for Valves

1. Why Preventive Maintenance is a Must

Valve maintenance plays a critical role of checking any small problem which may develop into a major issue in future. In this way, iron valves will last longer than if you did not regularly check and clean the valves, therefore saving a lot of time and money.

2. Globe Valve Maintenance Tips

Some of the things that should be considered of importance whenever you are planning on maintaining globe valves are the following:

Check that the status of the valve seat is eroded, worn, or cased, and decide to replace it.

Check if the overall operation of the stem is successful and lubricate it to avoid sticking.

It is also recommended that the valve body be cleaned so as to free it from any debris or sediment that may be present.

The recommended use of this type of gasket is to replace worn-out packing and gaskets to ensure a tight fit.

Preventive Maintenance for Globe Valves

In this way, you will be confident that your globe valves correspond to the flow rates you have established and are working effectively.

Avoid Common Valve Maintenance Mistakes

When carrying out valve maintenance, one is likely to make some mistakes that are dangerous to the systems in use. The following are error threats:

One common problem that emerges here is missing ordinary assessments to ensure that no deterioration has occurred.

Through the above-discussed details, it can be deduced that the following are the problems that may occur as a result of over-tightening the bolts:

Such as using unsuitable cleaning agents or lubricants on varieties of valve which can cause corrosion on the valves materials.

Skipping on replacement of the worn gaskets of seals thus leads to cases of leakage.

It is thus important to avoid the above mistakes and follow the recommended best practices in order to increase the lifespan and effectiveness of your valves.

Final Thoughts on Valve Maintenance

Valve maintenance is also proves to be really crucial for the proper functioning of your systems and mechanism. TOP Technical Notes EN By following the procedures, checklists and preventions described in this guide, minimum time for the vehicle halt, cost savings on repair and maintenance and the durability of the valves would be achieved.

To upgrade your system with high-quality valves, visit RUFSupply’s trunnion ball valve collection. Their products are designed to deliver maximum efficiency and durability in any application.