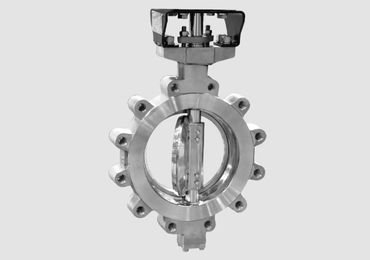

Triple Offset Butterfly Valve: The Ultimate Solution for Precision Flow Control

A triple offset Butterfly valve is a proven, reliable, and efficient choice for precision flow control in industrial applications. These valves have been designed to satisfactorily meet the most rigorous requirements, providing outstanding performance and durability capabilities as well as allowing some user-controlled flexibility. Whether you are searching for a manufacturer or know basic about simple type triple offset butterfly valve working principle, this guide is for you.

Triple Offset Butterfly Valve Specification

| Parameter | Specification |

|---|---|

| Valve Type | Triple Offset Butterfly Valve |

| Size Range | DN 80 – DN 2000 (3″ – 80″) |

| Pressure Rating | PN10, PN16, PN25, PN40, ANSI 150, ANSI 300, ANSI 600 |

| Body Material | Carbon Steel, Stainless Steel, Alloy Steel |

| Disc Material | Stainless Steel (SS304, SS316), Duplex Steel, Monel, Hastelloy |

| Seat Material | Metal-to-Metal Seal (Stainless Steel, Stellite, Alloy Coatings) |

| Stem Material | Stainless Steel (SS304, SS316), Duplex Steel, Inconel |

| Face-to-Face Dimensions | API 609, ISO 5752, EN 558 |

| Operating Temperature | -196°C to 600°C (-321°F to 1112°F), depending on materials |

| End Connection | Wafer, Lug, Double Flanged |

| Actuation Options | Manual (Gear), Pneumatic Actuator, Electric Actuator |

| Flow Direction | Bi-directional |

| Seal Type | Triple Offset Metal-to-Metal Seal |

| Leakage Class | ANSI/FCI 70-2 Class V or VI |

| Applications | Oil & Gas, Petrochemical, Power Plants, Cryogenic Services, High-Temperature Systems |

| Coating | Epoxy Coated, Fusion Bonded Epoxy, Special Paint as per customer requirements |

| Standards Compliance | API 609, ASME B16.34, ISO 5752, EN 593 |

| Installation Orientation | Horizontal or Vertical |

| Accessories | Limit Switch, Positioner, Solenoid Valve, Locking Device |

Triple Offset Butterfly Valve vs. Double Offset Butterfly Valve

It is therefore very important that one knows the difference between the triple offset butterfly valve and the double offset butterfly valve.

| Feature | Triple Offset Butterfly Valve | Double Offset Butterfly Valve |

|---|---|---|

| Design | Three offsets in the geometry ensure zero-contact sealing. | Two offsets reduce friction but may not achieve zero-leakage sealing. |

| Leakage Prevention | Provides absolute zero-leakage performance. | May allow minor leakage under high pressure. |

| Applications | Ideal for critical operations requiring precision and reliability. | Suitable for less demanding applications. |

| Lifespan | Longer lifespan due to reduced wear and tear. | Moderate lifespan with higher maintenance needs. |

Triple offset butterfly valve is suitably designed for application in high demanding and high performance industries and thus makes it suitable for most advanced processes in industries.

Different Types of Triple Offset Butterfly Valve

A triple offset butterfly valve features three offsets in its design, ensuring zero leakage, metal-to-metal sealing, and is ideal for high-pressure and high-temperature applications.

Send your Inquiry on RUFSupply Triple Offset Butterfly Valve Now

- Why Choose RUFSupply

- Technical Data

Custom Manufacturing

Tailored solutions to match your exact specifications, from materials to pressure ratings.

Rigorous Testing

Every valve is tested for performance, durability, and safety before shipping.

Expert Technical Support

Our team of engineers is available to help you select the right valve for your application.

Competitive Pricing

Direct manufacturing ensures no intermediaries, saving you costs.

Global Standards Compliance

Our valves meet API, ASME, DIN, JIS, and GOST standards, ensuring reliability worldwide.

Request a Quote Today!

Need a reliable trunnion ball valve for your critical operations? RUFSupply is your trusted partner for durable and high-performance solutions.

Technical Data

What is a Triple Offset Butterfly Valve?

A triple offset butterfly valve is a unique form of valve crafted to control opening and closing of fluid, gaseous and other substances in industrial processes. Unlike ordinary version, it has three offsets incorporated in it as they reduce the chances of wear and tear, leakages, and fighting making sure that the sealing is tight. These features place it in spotlight of usage in oil and gas, petrochemicals, power station, and water purification.

Key Features of a Triple Offset Butterfly Valve:

Flawless Sealing System: Due to the triple offset of the High-Performance Butterfly Valve, it provides non-leakage sealing even in high or low-pressure systems.

Durability: These designs cause less friction and therefore they do not wear out easily hence making the valve more durable.

Versatility: Suitable for a wide range of applications, from cryogenic to high-temperature environments.

Materials of Construction: Although most triple offset butterfly valves are hermetically constructed, they maintain an international standard such as API 609.

Advantages of Triple Offset Butterfly Valves

As for the advantages of investing in a triple offset butterfly valve, the following can be highlighted:

Zero Leakage: The design of the metal-to-metal lacks leakage, and therefore, the safety of the operation is guaranteed.

Little Maintenance: Due to the amount of friction of the valve, it means that the amount of maintenance required is low thus little time is wasted on this.

High-Temperature and Pressure Resistance: The valve performs well when used at high pressure and high temperature.

Convenient to Use: The fact that it is rather small and slim makes it easy to fix and operate.

Cost-Effective: This makes the maintenance of the structure longer than usual and therefore making it cheaper to use in industrial processes.

How Does a Triple Offset Butterfly Valve Work?

The basic characteristic of the triple offset butterfly valve working operation focuses more on the fact that it has three offsets.

First Offset:he shaft is located behind the plane of the sealing seat in order not to interfere with the operation.

Second Offset: The shaft is situated off the centerline of the valve body so that there will be little friction when it is opened and closed.

Third Offset: It has a conical sealing geometry which makes the sealing wall uniform in order to close off the leakage.

This is made in a way that makes the surface of the valve flange to have a smooth and direct contact with another corresponding metal surface which in turn making the ptfe lined valve to perform well even under very high pressures and temperatures.

Design Features of Triple Offset Butterfly Valves

Triple offset butterfly valve design itself speaks about the engineering in an effective and efficient manner. Key design elements include:

Disc and Seat Geometry: The disc and seat are conical in shape to provide the correct sealing system.

Metal-to-Metal Sealing: It increases the durability of the automotive parts and offers wear and tear resistance.

API 609 proves compliance with international standards: This ensures that the valve complies with the set and required International Standards.

Bidirectional Flange: It has provision for flow direction control in either direction, making it flexible for use in a wide variety of settings.

Applications of Triple Offset Butterfly Valves

These valves are used in many different industries mainly because of the versatility and efficiency. Common applications include:

Oil and Gas: Used in lubrication of equipment for controlling the flow of crude oil, natural gas and refined products.

Petrochemicals: Ensures safe and efficient operation in chemical processing plants.

Power Generation: They are used in controlling the temperature of steam as well as the cooling water in power plant industries.

Water Treatment: Ideal for desalination and wastewater treatment plants.

Cryogenic Applications: Performs reliably in extremely low-temperature environments.

Why Choose Us as Your Triple Offset Butterfly Valve Manufacturer and Supplier?

Being one of the most prominent manufacturers and suppliers of triple offset butterfly valves in China, our pride is stipulated in the provision of quality valves that are commensurable to the international standard. Here’s why buyers trust us:

Expertise: A wide range of years of experience in the creation and production of industrial valves.

The concept of custom solutions means that Flender can offer individual valve solutions for all the application needs.

Global Reach: Trusted by clients across industries worldwide.

Affordability: Pricing is done at a cheap yet reasonable cost without compromising on the quality.

Delivery Services: There will be fast and reliable delivery services to the specified destination.

This is evidenced by our vision and company goals where focusing on such values makes us stand out among the suppliers.

Conclusion

Triple offset butterfly valve is the type which can be very useful to industries that need valves that are precise, strong and do not leak. This way you will be able to determine how it works, the benefits of using it, and the type of tasks it is suitable for doing. Approach us to get the most authentic triple offset butterfly valves that you can find in the market and are manufactured to perform to international standards.

Triple offset valves are typical of severe service applications such as steam service, LNG service and refining. Their ability to operate at extreme conditions means they can be used in industries which operate with high precision flow control and safety, such as power plants, petrochemical facilities.

Triple offset butterfly valves deliver less wear since friction plays no role. They make tight seals even after long periods of use, enabling them to be applied to high-pressure, high-temperature or corrosive systems. Their design is a significant factor which results in reduced need for maintenance.

Triple offset valves are suitable for cryogenic applications because of their fine sealing and characteristic to work correct in very low temperatures. They are widely used in LNG plant, Liquid nitrogen systems, and other Cryogenic Storage operation.

Maintenance requires inspecting the seal for damage, check to prevent debris buildup, inspecting the actuator for smooth functionality. Movable parts lubricated on a regular basis can prolong the lifkey of the valve and ensure that it operates properly in critical systems.

Installation demands accurate alignment with the piping system and satisfactory; there is nothing obstructing it (debris) in connection with the valve or flanges. Bolts must be tightened uniformly for lack of stress, and the valve must be checked for leaks and smooth operation before completion.

Metal seated valves have a long-lasting feature, and it has the strength to work under high pressure or with abrasive media. They retain excellent seal performance in extreme environments and, therefore, are suitable for industries as heavy-duty as oil and gas – where reliability exists as a no-compromise requirement.

Metal seated valves have a long-lasting feature, and it has the strength to work under high pressure or with abrasive media. They retain excellent seal performance in extreme environments and, therefore, are suitable for industries as heavy-duty as oil and gas – where reliability exists as a no-compromise requirement.