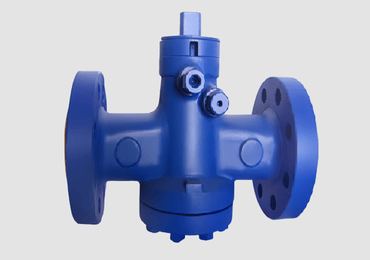

High-Quality Non-Lubricated Plug Valves for Sale – Durable, Reliable, and Affordable

Non-lubricated plug valves have gained popularity across industries that require maintenance-free, high, and optimal-performance flow control equipment. They are produced for various uses, including natural gas services, chemical services, and vital services within the industrial sector.

As a professional manufacturer and supplier of non-lubricated plug valves in China, RUFSUPPLY is committed to providing high-quality products that meet your requirements. The aim of this article is to provide the reader with information on the non-lubricated plug valves, what are the advantages and applications of the valves and how it is different from the lubricated plug valves.

Difference Between Lubricated and Non-Lubricated Plug Valves

In order to make a sound selection, this is important to differentiate between lubricated and non-lubricated plug valves.

Comparison: Lubricated vs Non-Lubricated Plug Valves

| Feature | Lubricated Plug Valve | Non-Lubricated Plug Valve |

|---|---|---|

| Sealing Mechanism | Requires grease or lubricant. | Uses elastomer or polymer seals. |

| Maintenance | Regular lubrication needed. | Low maintenance. |

| Environmental Impact | Risk of contamination. | Environmentally friendly. |

| Applications | High-pressure, high-temperature. | General-purpose and corrosive media. |

With regard to the lowest cost and less frequent need for reapplication, it is safer for the buyer to choose the non-lubricated version.

Different Types of Non-Lubricated Plug Valve

A non-lubricated plug valve uses a sleeve or elastomeric lining for sealing, requiring no lubrication, ideal for low-maintenance applications.

Send your Inquiry on RUFSupply Non-Lubricated Plug Valve Now

- Why Choose RUFSupply

- Technical Data

Custom Manufacturing

Tailored solutions to match your exact specifications, from materials to pressure ratings.

Rigorous Testing

Every valve is tested for performance, durability, and safety before shipping.

Expert Technical Support

Our team of engineers is available to help you select the right valve for your application.

Competitive Pricing

Direct manufacturing ensures no intermediaries, saving you costs.

Global Standards Compliance

Our valves meet API, ASME, DIN, JIS, and GOST standards, ensuring reliability worldwide.

Request a Quote Today!

Need a reliable trunnion ball valve for your critical operations? RUFSupply is your trusted partner for durable and high-performance solutions.

Technical Data

What Is a Non-Lubricated Plug Valve?

A non lubricated plug valve is a sort of quarter turn valve in which the rotation of the valve is by 90 degree to open or close the valve. As for the various types of plug valves, these types of valves have no rubbing surfaces as they incorporate a specially designed sealing system that is generally made of elastomer or polymer that exclude the use of oil.

Key Features:

- Low-maintenance design: No need for regular lubrication.

- Durable and corrosion-resistant materials: Ideal for harsh environments.

- Compact and lightweight: simple installation and can be operated using fingers.

Both buy new valves or replace old ones, non-lubricated plug valves can be considered to be quite efficient and economical.

Why Choose Non-Lubricated Plug Valves?

Non-lubricated plug valves have the following advantages that allow them to be used widely in production and processing plants all over the world. Here’s why they stand out:

1. Minimal Maintenance

Several advantages are associated with the operation of this machine, which includes the following: It does not require frequent lubricating. Hence, it incurs low costs.

2. High Durability

Their material is corrosion-resistant, and that is why these valves are well-suitable for extreme environments such as chemical or natural gas.

3. Leakproof Performance

These elastomer or polymer seals help to make the closing leakproof regardless of the pressure involved in the particular job or process.

4. Environmentally Friendly

Since there are no lubricants used in these cases, there is no risk of contamination and thus, such valves are more sustainable.

Non-lubricated plug valves from RUFSUPPLY are built to the highest quality to meet and excel in their specified application.

Applications of Non-Lubricated Plug Valves

Industries That Rely on Non-Lubricated Plug Valves:

- Natural Gas: Unlocking fluid control for ease of flow management in pipelines and processing plants.

- Chemical Processing: Handling corrosive and abrasive media with ease.

- Water Treatment: Providing reliable sealing for clean and wastewater systems.

- Refineries: Managing high-pressure and high-temperature applications.

Common Uses:

- Isolation of pipelines.

- Flow control in process systems.

- Emergency shut-off valves.

Namely, irrespective of the industry type in which you are operating or the specific type of valves that you require, RUFSUPPLY has the resources to offer you the ideal valves.

Non-lubricated plug is suitable to the industry’s reliable maintenance-free flow control. Common applications include:

Chemical Processing: Handling corrosive and abrasive media effectively.

Natural Gas Pipelines: Ensures safe and efficient flow management.

Water Treatment Systems: Provides dependable performance for clean and wastewater flow control.

Refineries: Suitable for high-temperature and high-pressure applications.

Some benefits of non-lubricated plug valves are:

Low Maintenance: No oil requirements to maintain its operation, thereby lowering operational costs.

Environmentally Friendly: Eliminates the risk of lubricant contamination.

Durability: Constructed with corrosion-resistant materials for long-lasting performance.

Leakproof Sealing: Elastomer or polymer gasket seals have watertight closure, even under changing pressure.

The chief characteristics of non-lubricated and lubricated plug valves differed:

Sealing Mechanism: Elastomer – polymer non-lubricated and lubricated with grease seals.

Maintenance: Non – lubricated valves maintain low maintenance activities whereas lubricated valves require periodic re – applications of lubricant.

Applications: General-purpose and corrosive fluids are more favourable to run with non-lubricated valves, while lubrication valves are best suited to high-pressure applications.

Non-lubricated plug valves need very little maintenance, such as:

- Inspect the seals for deterioration and replace them as needed.

- Keeping the valve clean to take out any blockage or deposit that can operate properly.

- Regular pressure testing is needed to achieve a hermetic seal.

- Verification of corrosion or damage on the valve body.

Yes, non-lubricated valve plug valves especially suitable for the corrosive substances owing to their solid structure and chemical resistance, all materials. Elastomer or polymer seals deliver reliable sealing without lubrication requirement, making them suitable for operating with aggressive pure low in industries also chemical processing and water treatment.

The most suitable materials for non-lubricated plug valves will depend on the applications and services to be experienced:

Stainless Steel: Ideal for corrosive environments and aggressive chemicals.

Ductile Iron: Suitable for general-purpose applications.

Alloy Materials: For high-temperature and high-pressure environments.

- Leakage: Check the seals; replace them if they are old or in bad condition.

- Difficulty to Operate: Check if there is debris or buildup within the valve and clean as needed.

- Low Flow: Check valve is fully opened and clear of any obstructions.

- Corrosion: Inspect the valve body for signs of corrosion and replace components if needed.