Metal Seated Ball Valve

Metal seated ball valves are designed to withstand extreme conditions which demand durability and performance in the applications that involve high temperatures and pressures with the abrasive medium. When contrasted with soft-seated valves, metal seated ball valves seal from metal against metal and thus are ideal for use in areas subject to mining, petrochemical, slurry, pulp, and refining industries. Their robust construction is ideally suited to resist wear and corrosion as well as thermal expansion, all the while assuring reliable sealing and longevity. These ball valves are commonly applied wherever soft seats would be compromised, when dealing with abrasive fluids or extreme high temperatures. They perform in critical operations which provide the least amount of unnecessary maintenance and downtime. These valves, manufactured with precision and made from high-end materials, are a reliable choice for any industry where flow control needs to be reliable and efficient under rigged operating conditions.

| Material Grade | A105,F304,F316, F51,F55 (Duplex Stainless Steel), F22 (Chromium-Molybdenum Steel), and alloys like Inconel (625, 825) or Monel (K500, 400) |

| Size Range | From 1/2″ – 52″ Full Port and Reduced port |

| Pressure Rating | Class 150,Class 300,Class 600,Class 900,Class 1500,Class 2500 |

| Face To Face | ASME B16.10 Long Pattern,Custom to client request. |

| Flange End | ASME B16.5 Raised Face Standard, RTJ Available |

Different Types of Metal Seated Ball Valve

Send your Inquiry on RUFSupply Metal Seated Ball Valve Now

- Video

Metal Seated Ball Valve

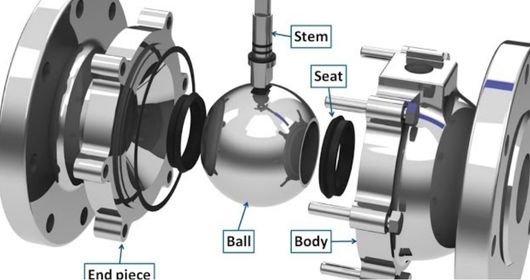

Figure 1: Metal seated Ball Valve Assembly

Metal seated ball valves are the superheroes of extreme industrial conditions: built to survive heat, pressure, and abrasives that would cause other to fail. Want fewer breakdowns; want greater efficiency, want valves that last? Read on to learn why they are your ultimate solution.

What is the metal seated valve?

Metal-seated valves are sealed by the contact of two metals; therefore, they can be applied broadly at a higher pressure or temperature than soft-seated types. Also, they last longer than soft-seated types despite external corrosion resistance. Developments in this category include: these valves are considered, in general, to operate High-Pressure products. They have ceramic or other hard alloy coatings; thus, they are suitable for wear resistance. One example is the metal-seated ball valve; this valve uses a ball and a seat that, when brought together, interrupt the escape of fluids. Such valves have applications in oil and gas, chemicals, and power generation, which require extreme temperatures or pressures that are not feasible for slurry applications.

Metal seat Ball Valve Types :

Metal-seat ball valves are meant for extreme conditions, extreme temperatures, abrasive materials, and critical applications. The difference between the soft seated and the metal seated sitting is that in a soft seated sitting, the sealing is maintained with the help of plastic or elastomeric material, while in metal seated sitting, it maintains the sealing with metal-to-metal contact. They are very durable for use in the oil and gas, petrochemical, power generation, and mining industries.

Metal seated Floating Ball Valve

The ball is not fixed and “floats” between the valve seats.

The sealing pressure is achieved when the upstream pressure pushes the ball against the downstream seat.

Best for smaller pipeline applications.

High resistance to wear and tear from abrasive media.

Common applications: steam systems, high-temperature pipelines, and processes involving particles or slurry.

Metal Seated Trunnion Ball Valve

The ball is then fixed in place using trunnions (mechanical anchors).

The valve seats press against the ball, forming a seal.

Minimal effort is needed to operate this valve in high-pressure applications.

This is highly suitable for larger pipelines and systems with pressure variations.

Common applications: oil and gas pipelines, LNG plants, and high-pressure steam lines.

Metal-seated valves: features

Metal-seated ball valves are designed and built to operate under high-pressure conditions, hence used in power generation systems, oil and gas, petrochemical, and mining industries. They are made to withstand tolerance to high temperatures and high pressure, and they are also suitable for abrasive or corrosive conditions. Below are the key features of metal-seated ball valves:

High Temperature and Pressure Resistance: Metals are capable of withstanding temperature and pressure above 1000oF, which is why they are ideal for severe service applications.

Durability and Wear Resistance: Ball and seat are frequently covered with wear-resistant materials such as tungsten carbide or chrome carbide. This results to the increased resistance of wear, abrasion and erosion particularly due to abrasive fluids or solid particulate materials.

Tight Shutoff Capability: Accuracy in the milling process guarantees proper metal-to-metal contact, especially under high pressure and temperature. This helps against leakage and raises operation safety standards.

Corrosion Resistance: Valves manufactured from materials such as stainless steel, Inconel, or Hastelloy can be used where the working fluid is corrosive or aggressively reacting.

Fire-Safe Design: Metal-seated valves conform to the fire-safe nature as the valve faces the seals made of metal, which enables it to work well even under fire conditions.

Metal-seated valves: benefits

Metal Seated Valves are few of the advantages.

Withstands Harsh Conditions

Ideal for use in corrosive, abrasive, or high pressure / high temperature environments where soft seated valves fail.

Extend product life of critical systems and take down time and maintenance.

Cost Efficiency Over Time

Though the initial cost is high, it sustains long-term operational expenses as their durability is high.

It saves money by maintaining longer intervals between maintenance or replacement.

Versatility Across Industries

In the oil and gas industries, petrochemical, power generation, mining, and water treatment.

Will handle high pressure steam and abrasive slurries.

Reliable Shutoff Performance

Avoid leakage under extreme conditions, to maintain the system integrity and security.

It reduces the environmental risks in hazardous material leak more.

Automation-Friendly

Seamlessly works with actuators for automating the control in complex systems.

The most efficient automation takes place especially in the case of large pipelines for trunnion mounted designs.

Typical severe service of metal seated ball valves

Metal seated ball valves are used in severe service conditions where high temperature, aggressive fluids or severe conditions make soft seated valves unsuitable. Their robust construction and metal-to-metal sealing make them ideal for the following industries:

Power Generation:

Application includes high temperature steam service such as steam header, turbine by-pass, and superheated steam service where temperature is above 1000°F in power plants.

Oil and Gas Application:

Ideal for use in high pressure applications such as pipelines, separators and flare gas systems, the metal seated ball valves are designed to work under pressures of up to 10,000 PSI and are not affected by corrosive hydrocarbons.

Mining:

Common in slurry lines and in tailings application, they are suitable for abrasive materials such as ore, sand or grit.

Chemical industry:

Some of their applications include acid handling, alkali injection and high corrosion systems where their coatings for instance tungsten carbide offers excellent chemical inertness.

LNG and Cryogenics:

Work effectively in very low temperatures of -320°F for liquefied gas transfer.

These valves are ideal for use in tough conditions to guarantee reliability and reliability.

When it comes to high temperature, high pressure and abrasive environment, metal seated ball valve is a perfect choice. Soft-seated valves used in these industries tend to fail in extreme conditions.

Soft-seated valves are best for low temperature and low pressure applications because they use PTFE for sealing. While, Metal seated valves are used for severe conditions ,when valves are subjected to a combination of high temperature, high pressure, and possibly abrasive or corrosive fluids.

Common ball valve issues include leakage, wear and tear of seals, and difficulty operating due to debris buildup. Regular maintenance and selecting the right valve type for specific conditions can help prevent these problems and ensure optimal performance.

Metal ball valves save on operational productivity, by decreasing downtime and maintenance costs in an extreme environment. Their strong build guarantees a longer service life, alike high-pressure, high-heat, or abrasive applications. This reliability reduces system interruptions and is thus a cost-efficient solution option for industries such as oil and gas or power generation.

Factors like operating temperature and pressure, fluid and the presence of abrasive or corrosive in it, should be considered when choosing metal seated ball valve. Also, use a material and coatings on the valve that can withstand the specific application to improve the durability and performance.

Metal seated ball valves are effective in the high-temperature or high-pressure applications although are not usually used in applications of cryogenic servicing. Extended temperature ranges that include very cold temperatures necessitate the application of specific version of cryogenic ball valves with soft seal or other modifications to withstand the foam associated with these conditions.

Regular maintenance consists of inspecting the valve for wear, checking for accumulation of debris, and applying necessary lubrication if so required. Placement of valves with proprietary coatings such as Tungsten Carbide is also available to provide abrasion resistance to the valve and increase the maintenance intervals.

Yes, metal seated ball valves is customised to exact client necessities – for example special stress scores, heat bad weather, of multi-type higher and lower coating. Manufacturers often design to order valves with their customers to meet their operational requirements.

Metal seated ball valves better for environment by giving of readiness to shut, helps in lowering the risk of leak in the systems which holds the hazardous material. Durability of their products also prevents the need for frequent exchange, removing plenty of waste and synthesized the practices.

Metal seated ball valves are widely subjected to tough industry standards, for example, API, ASME, and ISO. These tests confirm that the valves meet performance requirements for pressure, temperature and sealability under severe conditions. Always check that the supplier conforms to relevant industry standards for your application.

The size of a metal seated ball valve affects the flow principle, pressure loss, and the overall system performance. Larger valves are more suitable for heavy use, smallies for regulated mass forces in creature flow stys costs. Correct sizing will deliver the ultimate benefit of efficiency and reliability.

Yes, metal seated ball valves are able to handle multi-phase fluids; the mixtures of liquids, solids, and gas. Their heavy-duty construction and wear-resistant coatings make them suitable for demanding applications such as slurry pipelines or oil and gas separation system.

The life of a metal seated ball will depend on factors such as operating conditions, fluid type, and maintenance practices. In principle, these valves are made for long usage in demanding areas, in some cases above several years, by good care and routine maintenance.