If you are torn between selecting DBB vs DIB valves, it is also crucial to consider every aspect of the valves in relation to the system in which they are used. Whenever it comes to using pipelines, high-pressure systems or operations in generally dangerous conditions, it is crucial to spend some time and choose the right type of valve that will guarantee safety and stability and will fit the company’s budget. It is hoped that in this guide, you will find out what distinguishes between DBB (Double Block and Bleed) & DIB (Double Isolation and Bleed) valves, the uses of these valves, and how the valves are tested.

In conclusion, at the end of this article, you will be in a better position to decide on which valve type is the most appropriate for you and also on how to make this choice. Let’s dive in.

What Are DBB Valves?

DBB valves are used to isolate the pipe line from both ends at the same time and in addition, take out the pressure between the two sealing faces. Sanitary valves are particularly used in cases where there is need to work on a certain segment of the pipeline or to inspect it or check it without having to close down the entire system.

Key Features of DBB Valves

Two stops are situated on the elongated tube and are positioned to prevent the flow from both ends of the elongated tube.

A bleed mechanism to reduce the pressure that is trapped between the seals in the sanitary paper product.

Integrated design that incorporates several valves into one, leading to a small amount of space and installation cost.

Some of the industries that use nitrogen-handling DBB valves are the oil and gas industry, petrochemical and power generation, which require high degrees of reliability and safety.

What Are DIB Valves?

A double isolation and bleed valve, abbreviated to DIB, has the feature of double isolation where two independent sealing means are used even under the condition when pressure is acting in one direction only. In contrast to DBB valves, there is an isolation of the medium in the case of the use of DIB valves even if one of the sealing mechanisms has been compromised.

Key Features of DIB Valves

Two independent seals for enhanced safety.

Self-efficiency in being able to deal with stressful situations that are often encountered in high-risk jobs.

Suits best when backup power is needed most either in homes, commercial buildings or industrial uses.

These valves can help in applications where a single leakage may result in hazardous blow up such as in the offshore platform, chemical and process plants as well as in emergency shutdown systems.

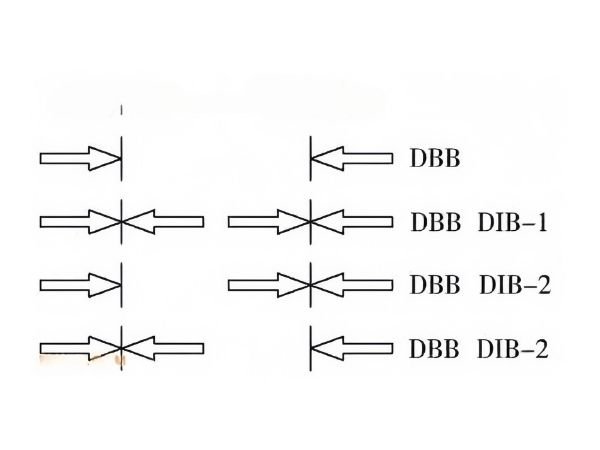

DBB vs DIB Valves: Understanding the Differences

Hereby, the main differences of DBB and DIB valves are explained by their design, as well as by their purpose. Here’s a breakdown:

Sealing Mechanisms

DBB Valves: ), two sealing surfaces are used to prevent flow from the two directions.

DIB Valves: Feature two sealing surfaces, that is to say, it has backup ability for safety.

Applications

DBB Valves: Used in pipeline maintenance, drainage and pressure gauge exclusion and other uses.

DIB Valves: Used especially for safety related applications in severe service› operations, emergency shutdown condition and hazardous applications.

Safety Standards

DBB Valves: This type of valves offers the feature of isolation only or employs some measure of separation while others work on the sealing of the hubs only.

DIB Valves: Recirculation features and check valves are safer because they have separate seals to afford safety even in failure.

By doing this it will be understood on which system to base a choice depending on the capacity needed and on the safety measure.

DIB Valve Animation: How It Works

If one is not conversant with DIB valves, then there is always the DIB valve animation that is used to demonstrate how the DIB valves work. These animations also show how the two independent seals function in such a manner as to prevent leakage of the flow, ensure safety and shed off pressure.

I believe animations are highly beneficial for training, as they allow for a better look into these valves and their functions with your team. They can also break down concepts into smaller elements, through which it is easy to convince all stakeholders on the gains.

Applications of DBB and DIB Valves

It becomes very important for one to differentiate between the two types, DBB valves and DIB valves in order to choose the suitable one to use.

Common Applications of DBB Valves

Isolation of pressure gauges and instruments during maintenance.

Pipelines are used for the purpose of inspecting or replacing certain parts of the pipeline to eliminate blockages and to allow fresh air access.

During system testing, it is very important to ensure that the working environment for the staff involved is safe.

Common Applications of DIB Valves

Emergency shutdown systems in high-pressure environments.

Risk is highly sensitive when addressing offshore platforms or refinery processes.

Some demanding operations require chemicals to be isolated with multiple functional barriers.

Every one of these valve types is designed for a particular service, and therefore, the conditions of operation of the system in which these valves are installed must be taken into consideration before selecting the proper type.

The tests on Californian Core-1, DIB-2 Valve and DIB 1 Test had the following procedures:

In order to achieve the usability and safety of the valves necessary testing procedures are conducted. The two commonly conducted tests are the DIB-2 valve test and one the DIB 1 test.

DIB-2 Valve Testing

This test aims at comparing the two sealing mechanisms based on their performance when placed under operating conditions. It makes certain that the valve can close off pressure no matter which seal has failed.

DIB 1 Test

The DIB 1 test is concerned with the working ability of individual seals, and it is used to confirm that any of them has the ability to create pressure isolation.

These tests play an important role of ensuring that the valves meet set standards and can withstand the pressures of the system.

How to Choose Between DBB and DIB Valves

Several factors are on which valve should be chosen through these aspects: But let the following factors be of consideration;

1. System Pressure

In high pressure, the DIB valves are more effective because they have two sealing systems.

2. Safety Requirements

DIB valves are ideal for power plants, oil rigs, and chemical firms among other companies whose systems work under unfavourable conditions.

3. Maintenance Needs

DBB valves are easier to maintain when it comes to routine work and therefore they are cheaper than the others. They are particularly good for environments where inevitable system failure seldom results in the loss of lives.

4. Application Type

Look at the role played by the valve in its specific application in the system. For instance DBB valves are best suited to isolate pressure gauges and on the other hand DIB valves are best suitable for emergency shut down services.

As for all-round and high-pressure valve, you may need to know the trunnion ball valve that is typically paired with DBB and DIB valves. These valves provide long service and high resistance and therefore are most suitable for high pressure usage. For more detailed information, refer to this Complete Guide to Trunnion Ball Valves to realize how it may improve your system.

Benefits of Using the Right Valve

It is therefore advantageous to use the correct valve for the system in the following ways:

Listed below are five great ways that Pointman upgrades the traditional epoxy system to make it safer for its clients and clients’ patrons.

Business Functionality : Enhance the functionality of your business.

Reduced Downtime: Minimize maintenance requirements and system interruptions.

Money Saving: There is no need to use cash frequently for repair works or changing parts that are destroyed by winds.

Meaning that by choosing the right choice of valve you will be assured of long term productivity and output as well as less costs.

If you want to learn more about the contemporary valve technologies, you may continue your search outside of the course and look up the Valve Manufacturers Association of America. This is an important source of information to know the trends, norms, and developments occurring in the AEC industry.

Conclusion

Therefore, deciding between the two types of valves, namely the DBB and the DIB valves does not have to be a difficult task. To assist you in avoiding the overlapping of functionality and maximize the value that each product offers, to you and your system, it is helpful to understand the differences and uses of both programs. Regardless of the factors that mean most to any process like safety, performance, and the cost of operation, the right valve is vital for the success of operations.

If you want to learn more on the next steps, then be free to read this link on our Complete Guide to Trunnion Ball Valves.