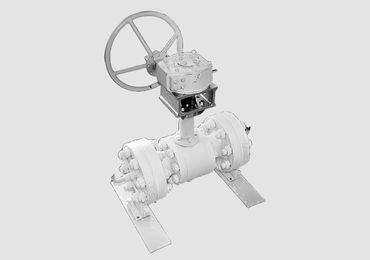

Cryogenic Ball Valves for Industrial Applications

What Is a Cryogenic Ball Valve?

A Cryogenic Ball Valve is a cryogenic valve applied to control or shut off cryogenic fluids, which are low-temperature fluids like gases either in gaseous or liquid state, including nitrogen, oxygen, hydrogen, Carbon dioxide and LNG. One of these fluids is stored and transported at very low temperatures, sometimes even at as low as -196OC / -320OF temperature e and requires valves that will not seize, fail or leak under such low temperatures.

This is the type of valve, cryogenic ball valves, that the various industries search for, for safety, efficiency and reliability of equal to that of the industries’ standard. The main products of the company include their patented ball valve sector, with their product used across a range of sectors including; LNG production, aerospace applications, medical systems and much more.

| Specification | Details |

|---|---|

| Valve Type | Cryogenic Ball Valve |

| Material | Stainless Steel (304/316), Duplex Steel, Super Duplex Steel |

| Size Range | 1/2″ to 12″ |

| Pressure Rating | 150 PSI to 600 PSI |

| Temperature Range | -196°C to 120°C (-320°F to 248°F) |

| End Connections | Flanged, Threaded, Welded |

| Standards | API 6D, ASME B16.34 |

| Applications | LNG, Liquid Oxygen (LOX), Liquid Nitrogen (LN2) |

Key Characteristics of Cryogenic Ball Valves

- Leak-Proof Design: Sealing is done very efficiently so that no pressure or ultra-low temperature compromises the barrier and causes leakage.

- Temperature Resistance: Versatile to operate in sub-zero temperatures and possesses a strong internal structure.

- Durable Materials: Fabricated from stainless steel or cryogenic-grade alloy to withstand corrosion and thermal stresses.

- Compact Design: The quarter-turn ball valve mechanism is easy to rotate and contributes to the valve’s efficiency.

This is so because cryogenic ball valves comply with internationally recognised standards like ISO 15848-1 and API 6D, to name but a few. Thus, reliability is required for critical offerings.

Different Types of Cryogenic Ball Valve

ensures reliable flow control at extremely low temperatures.

Send your Inquiry on RUFSupply 3-Way Ball Valve Now

- Video

- Why Choose RUFSupply

- Technical Data

Custom Manufacturing

Tailored solutions to match your exact specifications, from materials to pressure ratings.

Rigorous Testing

Every valve is tested for performance, durability, and safety before shipping.

Expert Technical Support

Our team of engineers is available to help you select the right valve for your application.

Competitive Pricing

Direct manufacturing ensures no intermediaries, saving you costs.

Global Standards Compliance

Our valves meet API, ASME, DIN, JIS, and GOST standards, ensuring reliability worldwide.

Request a Quote Today!

Need a reliable trunnion ball valve for your critical operations? RUFSupply is your trusted partner for durable and high-performance solutions.

Technical Data

How Does a Cryogenic Ball Valve Work?

The working of a cryogenic ball valve is quite straight forward in design but is immensely effective in its operation. This type of valve uses a control element that takes a spherical ball with a hole passing through its centre, referred to as the ball bore.

Turning 90 degrees to the left or right, the hole in the ball lies across the pipe to enable the fluids to pass—this is the open position. When the hole is aligned to flow with the pipe, the ball halts the fluid flow—this is the closed position.

Features That Enable Cryogenic Ball Valves to Function in Extreme Conditions

Extended Stem Design:

Lifting and extending the valve stem is continued until the working part such as the actuator or the handle is not in any case near the cryogenic fluids to freeze. This does help to prevent freezing at the stem, so effective operation of the mechanism where the temperature may be as low as minus a hundred degrees Celsius.

Cryogenic-Grade Seals:

Other reflex sealing systems; such as the soft seal or the metal seal mechanism is used. These seals are intended to be flexible with adequate strength at a temperature slightly below the freezing point. The conventional materials are PTFE or any material that should be suitable for the low temperature environment operations.

Pressure Relief Feature:

Density pressure with enclosed fluids that may be liquid to gas or gas to liquid through pressure variation is normally associated with conventional pressure relief holes within the ball of the cryogenic ball valves.

Material Selection:

Cryogenic-grade alloys and stainless steel materials are chosen because of their ability to handle short-crack-growth due to thermal contraction or expansion.

Types of Cryogenic Ball Valves

Cryogenic ball valves can be purchased in several styles to address the requirements of any industry.

Every class is intended for definite assignments and operating circumstances.

1. Top Entry Cryogenic Ball Valve

Description:

These top entry valves are particularly designed with provisions for ease of maintenance. The design

enables technicians to access the internals of the valve, such as the ball and the seals, without

removing the valve’s body from the pipeline.

Applications:

LNG terminals and storage systems. The US alone has invested $15 billion in these facilities.

Cryogenic pipelines where interruptions in service are costly or undesirable.

2. 3-Way Cryogenic Ball Valve

Description:

This valve has three orifices, so it can redirect the flow differently or mix fluids.

Applications:

Gas distribution networks.Systems that involve flow alteration or mixing procedures, such as chemical generation or LNG

vaporizing apparatus.

3. Fastene Half Floating Cryogenic Ball Valve

Description:

A kind of minuscule and thin valve in which the ball is not a fixed closure member but floats in the fluid

pressure.

Applications:

Cryogenic storage vessels for small-scale uses.Facilities such as hospitals and laboratories that deal with cryogenic gases.

4. Cryogenic Ball Valve with Trunnion Mounted

Description:

This valve employs a trunnion operation to support the ball and is best used in high-pressure systems.

Applications:

High-pressure LNG pipelines.Industrial-scale systems, such as large-scale cryogenic industrial setups.

5. Exclusive: Full Bore and Reduced Bore Valves

Full Bore:

The ball bore matches the pipe diameter to avoid pressure drops, ensuring maximum flow rate.

Reduced Bore:

The ball bore is smaller than the pipe diameter, sacrificing some flow rate but saving costs.

Applications:

Both types are chosen based on application needs such as flow configuration, pressure class, and ease of maintenance.

Construction and Material of Cryogenic Ball Valves

The handling of cryogenic ball valves is rather specific because the valve operates in environments where temperatures will be extremely low. Still, the design will have to be made in such a way that will allow for safety, durability, and efficiency.

Key Design Features:

Extended Bonnet and Stem: It allows for keeping packing and sealing outside of the influence of cryogenic liquid to prevent freezing.

Anti-Static Device: Eliminates static electricity, which correlates significantly with explosive danger when working with flammable cryogenic fluids like LH and LNG.

Cryogenic Testing: Cryogenic testing of each valve subjects it to a range of extreme conditions in terms of low temperatures.

Double Sealing: Some cryogenic ball valves employ a double sealing method that ensures the valve is safe and will not leak.

Materials Used in Cryogenic Ball Valves:

Stainless Steel (304/316): It comes with characteristics such as corrosion resistance and strength.

Monel or Inconel Alloys: These are for extra strength and used in conditions requiring higher operating temperatures.

PTFE or PCTFE Seals: Offer flexibility and sealing performance when used in fossil fuel handling equipment in cryogenic conditions.

Applications of Cryogenic Ball Valves

The cryogenic ball valves are unique for industries utilizing liquefied gases or industries requiring ultra-low temperatures. Here are some examples of their applications:

LNG Terminals and Storage

Cryogenic ball valves provide control during LNG storage, transportation, and regeneration processes. Because of their working pressure and operations at subzero temperatures, they can suitably be applied in LNG pipelines and storage tanks.

Aerospace and Rocket Propulsion or Aircraft Propulsion

Found in systems controlling cryogenic fuels such as oxygen and hydrogen employed in rockets. The elongated stem configuration minimizes the risk of freezing while offering safe usage when transferring propellants.

Medical Applications

Cryogenic ball valves are installed with biological substances at very low temperatures in cryopreservation equipment. They are also used in medical gas supply for oxygen and nitrogen mediation.

Chemical Processing

Cryogenic ball valves are utilized in the chemical industry to control the circulation of liquefied gasses in low-temperature reactions or storage.

Food and Beverage Industry

These are employed in freezing and storage applications while carbon dioxide or liquid nitrogen ball valves control their movement.

Energy Sector

In renewable energy systems such as hydrogen fuel cells, cryogenic ball valves are used to control the flow of liquid hydrogen.

Why Standards Are Important for Cryogenic Ball Valves

To meet safety, reliability, and efficiency requirements, cryogenic ball valves must comply with international standards. These standards ensure proper construction, functionality, and performance in critical systems. Common standards include:

ISO 15848-1: Characterized by low fugitive emissions and no leakage, ensuring environmental safety.

API 6D: Focuses on the design and functionality of pipeline valves for safe and efficient operations.

BS 6364: Outlines the general requirements for cryogenic valve construction and testing regimes.

When these standards are met, cryogenic ball valves operate safely and reliably in critical systems, ensuring long-term efficiency and security.

Cryogenic ball valves are used in the industries such as LNG production, aerospace, medical systems, chemical processing, food and beverages, and renewable energies industries.

Cryogenic ball valves can be used in conditions of extremely low temperatures; the valve can have an extended stem, the sealing is constructed of cryogenic materials, pressure relief is provided in order to prevent freezing of the valve.

Some of the factors are compatibility of the material, burst pressure rating of the valve, temperature limit and end connection type that is flanged, butt welded, screwed or socket welded and so on and conformance to the well recognized standards such as API 6D and ISO 15848-1.

Stainless steel (304/316), duplex steel, super duplex steel, Monel, and Inconel alloys can be typical materials because of their rigorous mechanical properties, high corrosion and heat treatment resistance.

The actuator or handle that is part of this stem design is sited further from the cryogenic fluid so it does not get frozen, and this makes it easier to operate.

Cryogenic ball valves many contain pressure relief holes so that the State change of the material media like, for example: from liquid phase to gaseous phase or from gaseous to liquid can be permitted and cannot pose any risk of pressure build up.

Cryogenic ball valves are also tested at cryogenic temperature, leakage test and pressure test in order to operate in extreme conditions.

Yes cryogenic ball valves contain anti-static devices to eradicate static electricity causes of explosion particularly incase of flammable gasses such as hydrogen or LNG.

Some of the configurations include top-entry, side-entry, 3-way, trunnion-mounted, full bore and reduced bore configurations each appropriate for certain functions.

Full bore valves allow the least pressure drop and maximum flow and are suited for application where flow rate must be maintained.

Yes, cryogenic ball valves’ use of actuators enables them to be operated automatically in different processes industrially.

Difficulties are associated with the increase in material’s brittle behavior at low temperatures, sealing ability, and maintaining the same performance under thermal cycling conditions.

They are known to be used in cryogenic services like liquid oxygen (LOX) services under certain conditions of cleanliness and compatible material specification.

It also requires ordinary examinations, greasing of all making contact part, and checking the condition of seals for permanent or lengthy usage and reliability of the device.

However, the expected life span of the operating depends on the conditions under which it is operated together with the maintenance which ranges between 10 to 20 years.

Cryogenic ball valves in LNG services play a critical role maintaining reliable flow control and prevent leakage at the same time at sub-zero temperature conditions in storage, transport and regasification.

Sudden changes in temperature and pressures or wrong material selection and an unsuitable sealing system interfere with the performance of the valve.

Safety is liberally provided in cryogenic ball valves due to compliance with international safety standards, the use of high grade materials, double sealing for the valve body and pressure relief mechanisms.

Stainless steel has high corrosion resistance, mechanical strength and thermal shock resistance to be adapted for cryogenic service.

Yes cryogenic ball valve mainly focuses on handling fluid within cryogenic temperature both in liquid and gaseous phase.