Carbon steel valves and stainless steel valves are two important types of industrial valves. They help control the flow of liquids or gases in factories and other places. Each type of valve works best in different situations, and knowing how they are different can help people choose the right valve for their needs.

In this guide, we’ll explain what makes these two types of valves special, where they are used, their technical specifications, and why it’s essential to pick the right one. By the end, you’ll understand why these valves are so useful and how they contribute to better performance in high-pressure and high-temperature applications.

What Are Carbon Steel Valves?

Carbon steel valves are special devices used to control the flow of liquids or gases in pipelines. They are made of carbon steel, a material that consists mostly of iron mixed with a small amount of carbon (between 0.05% and 2.1%). This combination provides excellent strength and heat resistance, making carbon steel valves ideal for high-pressure applications. Common types of carbon steel used include A216 WCB and A216 WC1, which are known for their toughness and durability.

Carbon steel valves are widely used in industrial applications, including power plants, oil and gas pipelines, and high-pressure steam systems. They are particularly suited for harsh conditions where strength and reliability are critical.

Advantages of Carbon Steel Valves

- Strength: Carbon steel is strong enough to handle high pressure and temperature. It can also be reinforced to meet specific application requirements, making it a preferred valve material for industrial use.

- Temperature Resistance: Carbon steel performs well in both high-temperature and low-temperature environments, making it versatile for various applications.

- Cost-Effective: Carbon steel is less expensive than stainless steel, offering a budget-friendly option for durable valve bodies.

- Weldability: Carbon steel is easy to weld, which is crucial for manufacturing custom piping systems and valve bodies.

Disadvantages of Carbon Steel Valves

1. Corrosion Characteristics: Carbon steel is prone to rust and corrosion when exposed to moisture or corrosive environments. Protective coatings or paints are necessary to prevent damage.

2. Heavy Weight: Carbon steel valves are heavier than stainless steel valves, making transportation and installation more costly.

3. Resistance to Chemicals: Carbon steel valves are less effective in corrosive environments compared to stainless steel valves.

Applications of Carbon Steel Valves

- Oil and gas pipelines.

- Power plants.

- Industrial processing systems.

- High-pressure steam systems.

- Refineries and chemical processing plants.

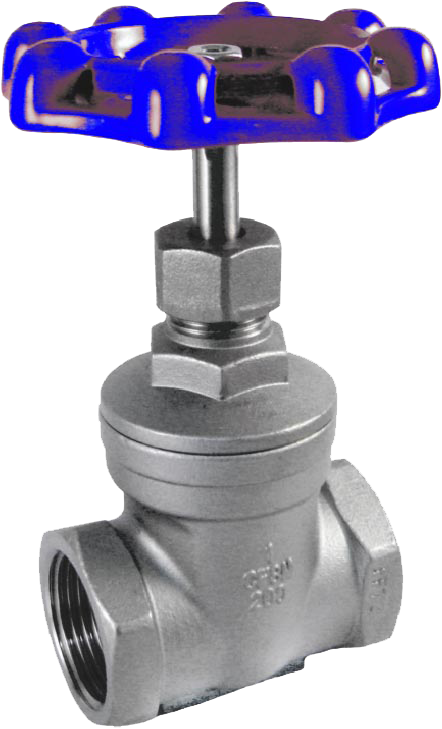

What are stainless steel valves?

Stainless steel valves are made from an alloy of iron and chromium (at least 10.5%), often with nickel. The chromium gives them excellent corrosion resistance, making them ideal for industries where hygiene is critical, such as food and beverage or pharmaceuticals.

Their rust and corrosion resistance also makes them suitable for harsh environments like chemical processing plants, marine systems, and water treatment facilities.

Advantages of Stainless Steel Valves

- Corrosion Resistance: Stainless steel is highly resistant to rust and oxidation, making it suitable for corrosive environments.

- Durability: Stainless steel can endure harsh conditions for many years without significant wear.

- Chemical Resistance: It resists acids, alkalis, and other corrosive chemicals, ensuring long service life.

- Hygienic and Appealing Finish: Stainless steel’s smooth surface is ideal for food and beverage processing or pharmaceutical applications.

- Low Maintenance: Its resistance to corrosion reduces upkeep costs, saving money over time.

Disadvantages of Stainless Steel Valves

Cost: Stainless steel is more expensive than carbon steel due to the materials and production process.

Lower Performance in Extreme Temperatures: Stainless steel is less effective than carbon steel in high-pressure and high-temperature applications.

Harder to Machine: Stainless steel’s hardness makes it more challenging to shape during manufacturing.

Applications of Stainless Steel Valves

- Food and beverage processing.

- Pharmaceutical production.

- Marine and offshore systems.

- Water treatment facilities.

- Chemical plants.

Technical Specifications: Carbon Steel Valves vs Stainless Steel Valves

The table below compares carbon steel valves and stainless steel valves based on key technical parameters:

| Specification | Carbon Steel Valves | Stainless Steel Valves |

|---|---|---|

| Tensile Strength | 250 MPa – 485 MPa (depending on grade) | 170 MPa – 310 MPa (depending on grade) |

| Temperature Range | -29°C to 425°C (A216 WCB) | -60°C to 815°C (304/316 stainless steel) |

| Corrosion Resistance | Low (requires coating or painting) | High (resists acids, alkalis, and saltwater) |

| Density | 7.85 g/cm³ | 7.75 – 8.1 g/cm³ |

| Weldability | Excellent | Moderate (requires professional welding) |

| Hardness (Brinell) | 120 – 200 HB | 150 – 200 HB |

| Thermal Expansion | 11.7 µm/m°C | 16.0 µm/m°C |

| Durability | Good for high-pressure systems | Excellent for corrosive environments |

| Cost | Lower upfront cost | Higher upfront cost but lower maintenance |

Key Differences Between Carbon Steel Valves and Stainless Steel Valves

- Rust Protection:

- Stainless steel valves resist rust due to their chromium content, making them ideal for corrosive environments.

- Carbon steel valves, lacking this protective layer, require coatings or paint to prevent rust.

- Strength:

- Carbon steel is stronger than stainless steel, excelling in high-pressure applications.

- Heat Tolerance:

- Stainless steel valves tolerate higher temperatures better than other materials.

- Cost:

- Carbon steel valves are less expensive, making them suitable for budget-conscious projects.

- Applications:

- Carbon steel is commonly used in power plants and high-pressure systems.

- Stainless steel is preferred for marine environments, food processing, and sanitary applications.

Are stainless steel valves better?

Sometimes, yes! Stainless steel valves are ideal when preventing rust, which is the main concern. They work best in water or chemical environments because stainless steel resists corrosion very well. However, stainless steel does not always guarantee better results.

Stainless steel is more expensive than other materials, which increases the overall cost. It is also harder to manufacture, and sliding parts are more likely to wear or get damaged.

To make valves effective and affordable, engineers often combine materials. For example, a brass valve has a brass body because it is strong enough and costs less. The ball inside, which is the most important part, is made of stainless steel because it resists rust. PTFE plastic is used for seals and packing because it is durable and doesn’t react with chemicals.

Engineers design valves for specific uses. A bathroom water valve only needs simple materials, while a valve for chemicals or rockets must include stainless steel or other special components. The choice of materials always depends on what the valve is used for.

Stainless steel valves are great at resisting rust, but they aren’t always necessary. Engineers must consider how a valve will be used before deciding which materials to use.

How to Select Carbon Steel vs. Stainless Steel Valves

Operating Environment:

Choose stainless steel valves for wet areas, saltwater, or chemical exposure. Opt for carbon steel valves in dry, high-pressure, and high-temperature systems.

Budget:

Carbon steel valves are cheaper upfront, making them a good choice if cost is a key factor. However, stainless steel valves may be more cost-effective in the long run due to their durability and low maintenance needs.

Industry and Use Case:

- Food, Beverage, and Pharmaceuticals: Use stainless steel valves for cleanliness and hygiene.

- Oil, Gas, and Power Stations: Choose carbon steel valves for their strength and heat resistance.

Longevity:

Stainless steel valves are ideal for corrosive environments, lasting longer with minimal upkeep. Carbon steel valves are better suited for physically demanding tasks and high-pressure systems.

Judge These Valves Based on Your Requirements

Your choice depends on your specific needs:

Choose Carbon Steel Valves If:

- You need strong resistance to pressure and heat.

- Cost is a significant concern.

- The environment does not expose the valve to moisture or corrosive chemicals.

Choose Stainless Steel Valves If:

- Corrosion resistance is critical.

- Your system involves fluids, chemicals, or sanitary processes.

- You require a durable product with minimal maintenance

Ready to Choose the Right Valve?

Assess your operation’s demands to find the right valve material for your performance, maintenance, and budget needs. Contact us today for expert advice on carbon steel ball valves, stainless steel gate valves, or other industrial valve solutions!