If you’re deciding between flanged vs. threaded connections for your piping systems, you’ve come to the right place. This guide will provide an in-depth comparison of these two connection types, their advantages, disadvantages, applications, and maintenance tips to help you make an informed decision.

What is a flanged connection?

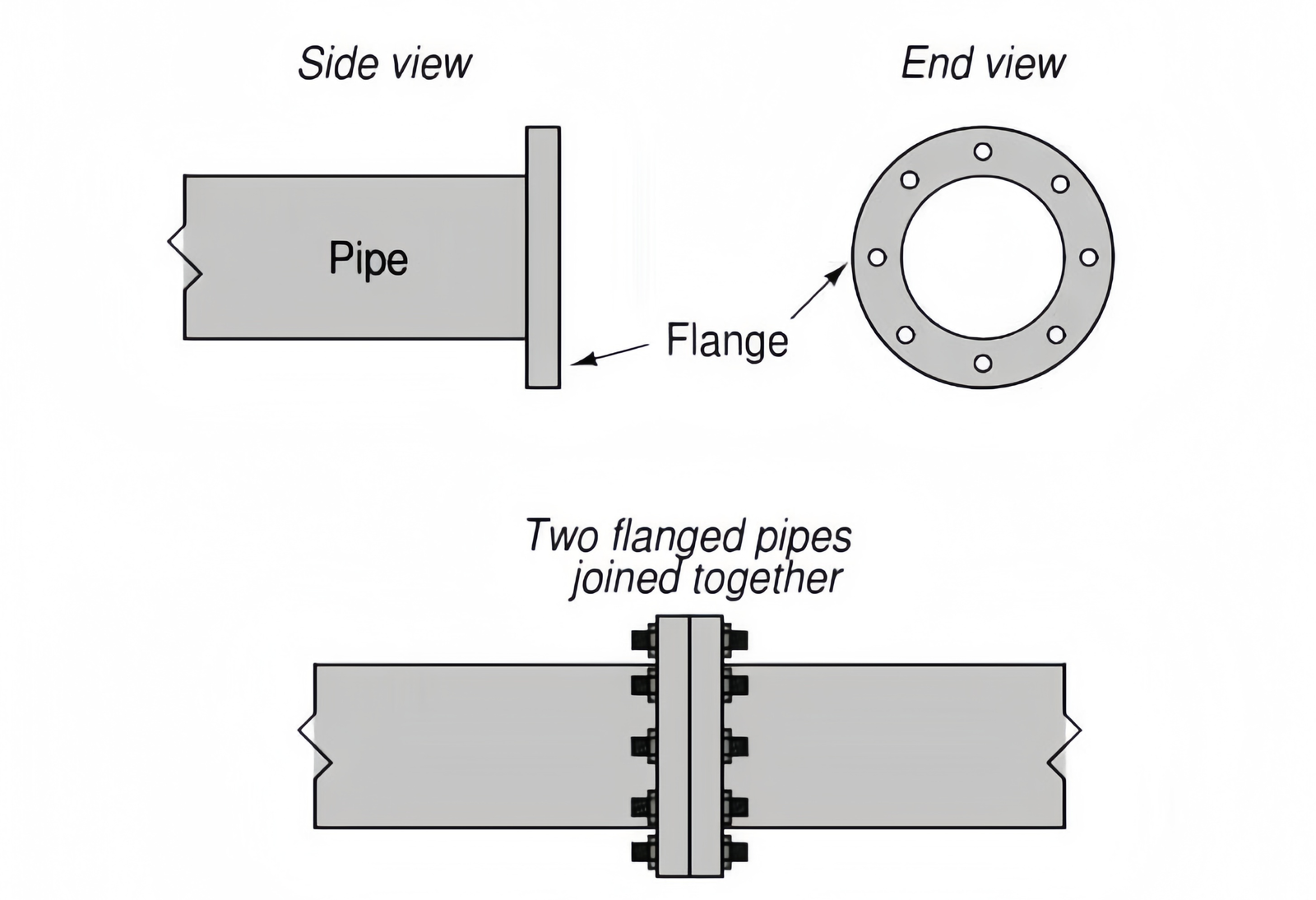

A flanged connection allows using a flange that works as the ring piece in connecting the pipes, the valves, or fittings. The connections are used in industrial systems, which demand strong and leak-tight joints that can withstand high pressure and temperature ranges. Welded flanges, butt weld flanges, and also others are included as examples.

Flanged connections are also suitable for situations where many situations require frequent disassembly and maintenance, for example, in chemical plants and water treatment chemical plants.

What is a threaded connection?

A threaded connection uses matching grooves on the pipe and valve ends to create a seal. Commonly found in smaller piping systems, threaded connections are compact, cost-effective, and easy to install. If you’re wondering, “what is a threaded connection?” it’s one of the oldest methods of connecting pipes and valves.

Threaded connections, such as threaded valves, are often used in residential plumbing, small-scale industrial setups, and temporary systems.

Comparing Flanged vs Threaded Connections

Below is a detailed comparison of flanged vs. threaded connections based on key factors:

| Feature | Flanged Connections | Threaded Connections |

|---|---|---|

| Pressure Handling | Suitable for high-pressure systems. | Best for low to medium-pressure systems. |

| Pipe Size | Commonly used for large pipe diameters. | Ideal for smaller pipe sizes (under 3 inches). |

| Installation | Requires more space and specialized tools. | Quick and easy to install with minimal tools. |

| Cost | Higher cost due to materials and components. | More cost-effective. |

| Maintenance | Easy to disassemble for inspection and repair. | Harder to disassemble and maintain. |

| Common Applications | Industrial systems, chemical plants, and high-pressure pipelines. | Residential plumbing, temporary setups, low-pressure systems. |

Applications of Flanged Connections

Flanged connections are widely used where durability and reliability represent key importance in industries. Common applications include:

- Oil and gas pipelines.

- Water treatment facilities.

- High-temperature chemical processing plants.

- Applications of Threaded Connections

Threaded applications are ideal or low cost, space and simple features. They are commonly used in:

- Residential plumbing systems.

- Small-scale industrial setups.

- Temporary or modular piping systems.

Maintenance Tips for Flanged and Threaded Connections

Flanged Connections

-

- Monitor gaskets and bolts for excessive wear or rusting on a routine basis.

- Verify the bolts have adequate torque to eliminate leakage.

- Clean flange surfaces are to be reinstalled to ensure a good seal.

Threaded Connections

- Do not over-tighten to avoid thread stripping.

- Apply thread sealants, or Teflon tape, to prevent leaks.

- Regularly check threads for any sign of wear or corrosion

FAQs About Flanged vs Threaded Connections

1. Which is the best: flanged or threaded?

The preference is yours to back. Flange connections should be used for high-pressure and large-diameter systems and threaded connections for low-pressure and small-diameter systems.

2. Can threaded connections work with high pressure?

Compressed connections also tend to be unsuitable in extremely heavy-duty applications because of the possibility for leakage and thread damage.

3. What is a common flange type?

The welded flange is one of the most common types, giving strong and durable joints for industrial.

Define Flanged Connections

A flange is to describe connecting pipes or fitting them together by means of flanges. These connections have the maximum number of uses for their strength, durability, and ease of dismantling.

Learn More About Flanged Gate Valves

If you’re considering a flanged connection, a flanged gate valve might be the perfect solution. These valves are designed for high-pressure applications and provide excellent sealing performance. Learn more about flanged gate valves today.

Related Resources

For more insights, explore our detailed guide on flanged vs threaded connections. You can also check out our valve actuators guide to find the right solutions for your system.