Buy High-Performance Manifold Valves: Types, Features, and Pricing

RUFSUPPLY company focuses on providing a manifold valve for industrial systems, which are of high quality. Our range of valves consists of 2-way, 3-way, and 5-way manifold valves; all of them are created with high levels of sturdiness and reasonable prices in mind.

Manifold valves are designed to be accurate, durable and adaptable to various applications such as oil and gas, chemicals and utilities. Learn more about the products, their functions and advantages, as well as make a purchase now.

Manifold Valve Specifications

| Parameter | Specification |

|---|---|

| Type | 2-Valve/3-Valve/5-Valve Manifold |

| Material | Stainless Steel 316, Carbon Steel, Monel |

| Pressure Rating | Up to 20000 PSI |

| Temperature Range | -40°C to 200°C (-40°F to 392°F) |

| Connection Type | Flanged, Threaded, Socket Weld |

| Standards | ANSI, DIN, JIS |

| Applications | Pressure Measurement, Differential Pressure Measurement |

| Sealing | PTFE, Graphite |

| Mounting | Direct Mount/Remote Mount |

Different Types of Manifold Valve

A Manifold Valve integrates multiple valves in a single unit, used for controlling, isolating, or distributing fluid flow in systems.

Send your Inquiry on RUFSupply Manifold Valve Now

- Why Choose RUFSupply

- Technical Data

Custom Manufacturing

Tailored solutions to match your exact specifications, from materials to pressure ratings.

Rigorous Testing

Every valve is tested for performance, durability, and safety before shipping.

Expert Technical Support

Our team of engineers is available to help you select the right valve for your application.

Competitive Pricing

Direct manufacturing ensures no intermediaries, saving you costs.

Global Standards Compliance

Our valves meet API, ASME, DIN, JIS, and GOST standards, ensuring reliability worldwide.

Request a Quote Today!

Need a reliable trunnion ball valve for your critical operations? RUFSupply is your trusted partner for durable and high-performance solutions.

Technical Data

Why Choose RUFSUPPLY Manifold Valves?

RUFSUPPLY company is also a professional manufacturer and supplier of manifold valves for global markets, including China, where customers will receive the following advantages:

High Durability: Built with stainless steel, carbon steel, or custom materials to withstand extreme conditions.

Accurate Performance: Manufactured with high precision to ensure that the system does not leak and to sustain usage for longer periods.

Affordable Rates: Cost-effectiveness can be achieved in any organization, especially when the company has competitive prices for their products or services without having to compromise quality.

Custom Options: Here we offer standard options that will be adjusted slightly for each customer and his needs.

Do not listen to us, and go through out Manifold Valve Collection to see which product is suited for your system.

What Is a Manifold Valve?

A manifold valve is identified as a crucial component in industrial systems that is employed for particular control, separation, or management of fluids or gases. Introducing these valves helps to decrease an overall number of elements in systems, to minimize the number of connections and, therefore, leaks, to increase the efficiency, and to decrease the maintenance expenses.

Key Features:

Isolation: The instruments, such as the pressure gauges and transmitters, should be safely isolated.

Equalization: Ensure the balance on the system in order to get correct readings.

Venting:A key aspect of pressure relief that enables one to prevent harm without causing any additional complications to the system.

Control: Alleviate fluctuations of fluid or gas production to a stable state.

Types of Manifold Valves We Offer

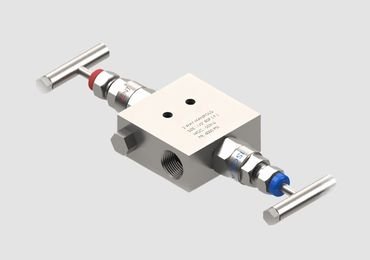

1. 2-Way Manifold Valves

The 2-way manifold valves are specifically designed for instrument isolation and calibration.

Features:

Compact and easy to install.

Leak-tight performance for critical systems.

Ideal for pressure transmitters and gauges.

Applications:

Pressure monitoring in pipelines.

Maintenance operations requiring isolation.

For more details on our 2-Way Manifold Valves, select a suitable solution for your system.

2. 3-Way Manifold Valves

This type of four-port valve is ideal for equalizing pressure and for breaking vacuum as well.

Features:

Equalization, isolation, and venting are three ports.

Durable materials for high-pressure environments.

Precision-engineered for differential pressure transmitters.

Applications:

Differential pressure measurement in industrial systems.

Applications that require fixed venting and also pressure equalization.

Choose your 3-Way Manifold Valves through a variety of choices and get them for the best prices and excellent operations.

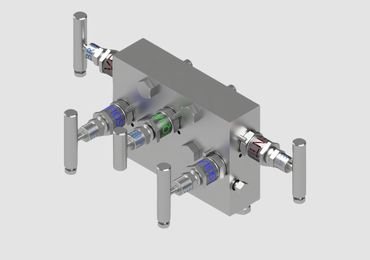

3. 5-Way Manifold Valves

Our 5-way manifold valves are developed at the highest level with functions of isolation, equalization, and venting in one valve.

Features:

Five ports for complex operations.

Simplifies multi-instrument configurations.

It says well to be used in high-pressure and high-temperature applications.

Applications:

Differential pressure measurement across multiple instruments.

These are systems where air’s capability to filter, flow, and balance needs to be adjusted.

Visit our astonishing Product Showroom and find out more about our 5-Way Manifold Valves.

Benefits of RUFSUPPLY Manifold Valves

1. Durability You Can Trust

For example, our manifold valves are made from stainless steel and carbon steel to guarantee for the valves to serve their task for a longer period of time no matter the working conditions.

2. Cost Savings

Our manifold valves are capable of combining multiple functions in one valve, thus decreasing system complexity and reducing leaks, which would be cheaper to maintain.

3. Versatility for Every Industry

This we offer a variety of viscosity levels of 2 way to 5 way manifold valves for the following industries namely; oil and gas, chemical processing and instrumentation.

4. Custom Options Available

Need a custom solution? It should also be noted that our manifold valves for your car are made specifically to order. Contact us today to discuss more about your application or view the product list of our Custom Valve Solutions.

Pricing and Availability

Consequently, at RUFSUPPLY, we offer high-quality manifold valves at a reasonable price in the global market.

What Affects Manifold Valve Prices?

Material Selection: Stainless steel or carbon steel options.

Valve Type: 2-way, 3-way, or 5-way configurations.

Special Requirements: Services may come with different prices depending on the customer’s specifications.

For the specific quote, please get in touch with us or refer to the Manifold Valve Prices section.

How to Assemble a Manifold Valve

It helps in ensuring that you end up with the right manifold valve with the ability to perform optimally. Here’s a quick guide:

Ensure the Component is Free from Damage or Debris: It is advised that before installing the components, some inspection is done to ascertain the components are not damaged with debris.

Ensure that the ports of the manifold valve correspond to the system piping or tubing.

Tighten the Connections: Do this to the recommended torque to avoid dripping.

Leak check: Specific to the valve, check for air leaks through a pressure test that must yield the correct pressure.

Also, it is advisable to keep servicing the air release valve in regular intervals to improve its performance and longevity.

Need help with assembly? Please, turn to the services of our support service or read our detailed Manifold Valve Assembly Guide.

A manifold valve is used to control, isolate, and regulate the flow of fluids and gases in industrial systems. It combines multiple control valves in a single compact housing to decrease the number of connections and the possibility of leak points. Used frequently in instrumentation systems, manifold valves are suitable for deployment in applications such as analysis of pressure, flow control, and differential pressure monitoring in oil & gas, petrochemicals, and water treatment industries.

The two systems mainly differ in their structural aspects and operational capabilities.

The 2-valve manifold provides pressure gauge and transmitter isolation and calibration functions. The device includes two separate functions for isolation and venting operations.

A 3-valve manifold exists for measuring differential pressure by supporting venting and, equalization and valve isolation functions.

5-valve manifolds unite isolation capabilities together with equalization capabilities with venting functions and also include supplemental ports to handle multiple instrument setups.

The manifold types operate for different applications because systems differ in complexity alongside their measurement needs.

Manifold valves are produced from tough materials for withstanding tough settings. Common materials include:

Stainless steel (316): Ideal for corrosive environments and chemical handling.

Carbon steel: It is recommended for high-pressure applications where corrosion resistance is low.

Monel: Used in marine and chemical industries for its superior corrosion resistance.

Choice of material is dictated by working fluid, temperature and pressure of the system.

Manifold valves of high-pressure offer many benefits:

Improved safety: Built to withstand 20,000 PSI system fail-safes.

Compact size: Houses multiple capabilities into one unit minimizing the system complexity.

Durability: Built with robust materials to withstand extreme operating conditions.

These valves are well-suited to high pressure systems in the oil and gas industries along with power generation.

In differential pressure measurement, a manifold valve provides accurate readings for the following:

Enclosure of the instrument: Protects against fluid interferences caused by maintenance or calibration.

Equalizing pressure: Excitory pressure balances across the transmitter in order to avoid damage.

Venting: Allows trapped pressure or fluid to be eased safely to prevent measurement errors.

This convenience makes manifold valves a necessary feature in instrumentation systems of an industrial process.

Choose manifold valve should cherish the following:

Manifold type: Select a 2-, 3-, or 5-valve design that meets your system requirements.

Material compatibility: Make sure that the valve material can withstand the fluid or gas in your system.

Pressure Range: Choose a valve listed to the maximum pressure present in your system.

Connection Type: Choose the connection that same as the valve’s connection (flanged, threaded or socket weld) and pipeline.

Proper choice assures the best operation and longevity of the valve.

To maintain manifold valves effectively:

- Check parts for problems such as leakages and unhealthy indications in seals and connectors.

- Remove unwanted materials from the ports to keep them working without problems.

- The device tests how well each part of the manifold valve works.

- Exchange the damaged seals or gaskets to stop fluid leakage.

Maintaining manifold valves on a regular basis keeps the valves working longer while delivering dependable results.

Stainless steel manifold valves are applied in various industries that demand valves with corrosion protection and accurate control, such as the following:

Chemical processing: For handling aggressive chemicals and corrosive fluids.

Oil and gas: This is utilized in offshore and high-pressure circumstances such as oil and gas facilities.

Marine: Suitable for those environments that comprise of some exposure to moisture and wet conditions.

The process: Ideal for operation of power generation in controlling the flow of steam and water to cool the equipment.

Because of its high durability and flexibility, it is favorably applied for critical applications.

Manifold valves streamlines industrial systems by:

Combining multiple functions: Isolation, equalization, and venting are combined into one unit.

Decreasing connections: Fewer connections mean fewer points of possible leaks, plus less during installation.

Maintenance simplification: Instruments installed for calibration or replacement can be accessed quickly to minimize downtime.

Such benefits enhance system efficiency and reduce the total cost.

Manifold valves are offered in the following connection types:

Flanged: Ideal for high-pressure systems and secure installations.

Threaded: Suitable for low-pressure applications and quick assembly.

Socket weld: Provides a secure, airtight joint for use up to high-temperature operations.

The connection style should be determined according to pressure required by the system, temperature of the system and installation application.