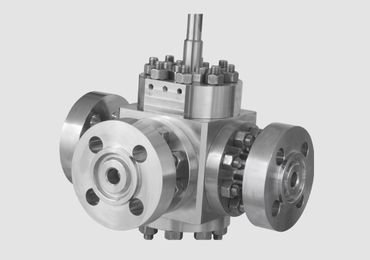

The Best 3 Way Ball Valve for Your Needs: Durable, Reliable, and Versatile

A 3-way Ball Valve has been designed to maximize fluid flow direction regulation in the most efficient way. A 3-way ball valve is a solution if you need a reliable valve for big or small-scale industrial applications or personal home plumbing. From standard T-port manual valves to more innovative pneumatically and electrically actuated options, RUFSupply supplies a wide range of premium options.

RUFSupply manufactures and stocks every 3-way ball valve we build for durability, reliability, and exceptional performance. Our valves are designed to endure heavy use, and this is how any application will work in our valves. RUFSupply gives you the best choice of high-quality 3-way ball valve, which is unmatched in the market. We will provide solutions that serve your needs and meet your expectations.

3 Way Ball Valve Specification

| Specification | Details |

|---|---|

| Type | 3-Way Ball Valve |

| Material | Stainless Steel, Carbon Steel, C95800, Duplex Steel, Alloy 20 |

| Size Range | 1/2″ to 4″ |

| Port Configuration | T-Port / L-Port |

| Pressure Rating | Class 150 to 2500lb |

| Temperature Range | -20°C to 200°C (-4°F to 392°F) |

| End Connection | Threaded / Flanged / Socket Weld / Butt Welded |

| Applications | Industrial, HVAC, Water Treatment |

Different Types of 3 Way Ball Valve

3-way ball valves are used as control and on/off for management of direction of the flow of fluids in T-Port or L-Port.

Send your Inquiry on RUFSupply 3-Way Ball Valve Now

- Video

- Why Choose RUFSupply

- Technical Data

Custom Manufacturing

Tailored solutions to match your exact specifications, from materials to pressure ratings.

Rigorous Testing

Every valve is tested for performance, durability, and safety before shipping.

Expert Technical Support

Our team of engineers is available to help you select the right valve for your application.

Competitive Pricing

Direct manufacturing ensures no intermediaries, saving you costs.

Global Standards Compliance

Our valves meet API, ASME, DIN, JIS, and GOST standards, ensuring reliability worldwide.

Request a Quote Today!

Need a reliable trunnion ball valve for your critical operations? RUFSupply is your trusted partner for durable and high-performance solutions.

Technical Data

What is a 3-Way Ball Valve?

A 3-way ball valve is a necessary controlling tool utilized to regulate the flow direction and sharing of different media (liquid, gas, or slurry) in three interconnected ports. These valves provide flexibility for applications such as:

- Switching between more than one pipeline.

- Combining two input flows with the resulting flow collected in a single output link.

- Not simply shutting the three ports altogether but shutting only one while keeping the flow in the remainder of the two.

This type of valve is extensively used by industries like Petrochemical, Oil and Gas, Water Treatment, and Chemical Processing industries because of its optimistic features such as the 3-Way Ball Valve’s endurance.

We offer these valves in several materials such as

carbon steel, forged steel, stainless steel, duplex steel, Alloy 20, and many more to meet various operating conditions.

How Does a 3-Way Ball Valve Work?

A 3-way ball valve operates through the movement of a ball with an aperture in the mid-portion of the valve channel bodily. This rotation, which is controlled, manually or through an actuator, defines the position of the bore relative to the ports, in order to govern the flow.

Depending on the configuration, which could be T-port or L-port the valve can be used for diverting, mixing as well as isolating a portion of the liquid. The icon of the valve shown in the system diagrams may show one or both flow characteristics and mode of operation of the valve.

Body Material

It is suggested that valve body construction materials are tough enough to include the following:

- Carbon Steel: Well-reputed for its durability to offer high-pressure applications.

- Forged Steel: Improves strength and sturdiness, which is appropriate for a challenging environment.

- Stainless Steel: Courageous and appropriate for conditions that require utilization in harsh environments.

- Duplex Steel: This is a high-strength alloy with great corrosion resistance, common in marine and chemical industries.

- Alloy 20: Mainly used in dispatching strong acids and highly corrosive chemical product collections.

Ball

A spherical member of which only the through bore determines the flow direction.

Ports

Screw the valve to three pipes, which are Pipe A, Pipe B, and Pipe C.

Actuation Mechanism

Controlled manually by a handle or can be powered with the help of pneumatic, electrical, or hydraulic actuating devices.

Additional Features

“It involves a spherical ball to indicate forward flow direction, ports to join three pipes (Pipe A, Pipe B, Pipe C) and an actuation that is hand-operated or power-operated through pneumatically operated, electrical operating, and hydraulic operating.”

— Functional Specifications

For more details, download the full PDF document containing the detailed drawings and assembly instructions for the 3-way ball valve:

Material Selection for 3-Way Ball Valves

Now that we know how 3-way ball valves work and how they are made, let us now discuss the appropriate material selection process for their construction.

“Selecting the proper material is essential for the operations and durability of valves. The wrong material can lead to failures, inefficiencies, and higher maintenance costs in demanding environments.”

Selecting the proper material, therefore, is essential in the operations and durability of valves. Below are the most commonly used materials:

- 1. Carbon Steel

Characteristics: High strength, high density, excellent thermal shock resistance – suitable for high pressure and high temperature use.

Applications: Oil and gas, power generation, and heavy industrial uses.

- 2. Forged Steel

Characteristics: Increased levels of workability in comparison with cast steel, as well as greater levels of wear resistance, making it more suitable for usage in harsh settings.

Applications: Refinery platforms, main pipelines, chemical industries, and offshore facilities.

- 3. Stainless Steel – Austenitic

Characteristics: Good and fast resistance to corrosion and chemical attack, suitable for the harshest environments.

Applications: Canning industries, industries that deal with pharmaceutical products, and chemical industries.

- 4. Duplex Steel

Characteristics: Is an alloy that incorporates the hardness of carbon steel reinforced with the corrosion resistance properties of stainless steel, making it ideal for use under harsh environments.

Applications: Marine industries, desalination industries, and industries involving chemical handling.

- 5. Alloy 20

Characteristics: Built for use in environments that require a high level of resistance to corrosion, especially in cases of sulfuric acid usage.

Applications: Chemical processing, pharmaceutical industries, and industries that involve the use of highly corrosive materials.

The application conditions include temperature, pressure, and media. Through knowing the operating parameters, a user can make the best choice to suit the valve.

Operation and Actuation Options

Manual operation and automatic operations can be used in the system depending on the operation of the 3-way ball valves.

- 1. Manual Operation

Conveniently, the aforementioned operated under a handle for primary control. Appropriate for small-scale systems or cases where changes are rarely to be made.

- 2. Pneumatic Actuator

Deploys compressed air as the flow control mechanism for handling valve operations. Especially suitable for those applications that require fast response and frequent changes in industrial processes.

- 3. Electric Actuator

Has high accuracy as it uses electric power to operate and is preferred for applications where they are out of reach physically.

- 4. Hydraulic Actuator

Hydraulically activated and intended for use in high-level pressure systems. Used mostly in large applications such as those that are found in industries.

Applications of 3-Way Ball Valves

Thanks to their versatile design and material options, 3-way ball valves are used in a wide range of industries:

- Chemical Processing

Contains and processes aggressive chemicals using equipment and equipment parts made from Alloy 20 and stainless steel.

- Oil and Gas

Working in the applications with carbon steel or forged steel valves in high-pressure transmission pipelines.

- Water Treatment

Desalination systems and water filtration applications should particularly use corrosion-resistant duplex steel valves.

- HVAC Systems

Regulates hot and cold water in heating as well as cooling systems.

- Marine Applications

Duplex steel valves are preferred because of their low tendency for corrosion when used in salty water environments.

Sizes and Configurations

3-way ball valves are available in diverse sizes and configurations to meet the needs of various industries:

- Sizes

Some of the often-used thicknesses are 1/2 inch, 3/4 inch, 1 inch, 1 ½ inch, and even 12 inch for commercial purposes.

- Connections

There are threaded, flanged, or welded types that can connect to any pipe systems available in the market.

Why RUFSupply for Three-Way Ball Valves?

Our company maintains Elite 3-Way Ball Valves where the quality, reliability, and the efficiency of supply plays our major concern at RUFSupply. Here’s why you should choose us:

- Material Variety

Whether carbon steel, alloy 20, or any other requirements with operating conditions, we have the valves for you.

- Custom Configurations

Decisions of manual, pneumatic, electric, and hydraulic actuators to be chosen based on its system type.

- Global Standards

All types of valves meet international design standards such as: ANSI, ASME, ISO, etc.

- Technical Support

The content of this site includes detailed PDFs of all the major products, drawings, and guidelines for installation and operational processes.

Looking for High-Quality 3-Way Ball Valves?

Contact RUFSupply today to get the best solutions for your needs!

There are three-way ball valves which are commonly used in oil and gas industries, chemical industries, water and treatment plants, HVAC systems and marine applications because of flexibility in controlling the flow of the fluid.

A 3-way ball valve has three ports which is used for direction control valve whereas a 2-way ball valve means flow control between two ports only either opened or closed.

Flow diverters or mixers are the most common application areas for 3-way ball valve making it more appropriate than the general gate or globe valve.

Yes, 3-way ball valves are capable of controlling the rate of gas flow, so long as the material of the value and the seals used is suitable to the type of gas and working pressure.

T-port valves are particularly suited for mixing or splitting flow while L-port valves being more suitable for redirecting the flow from one pipe line to the other or blocking off any port.

Its properties of high strength together with the capacity to handle high pressure and high temperatures makes it ideal for application in oil and gas transport conduits.

Duplex steel has platform suitability for harsh industries including marine and chemical processing industries since it has very high corrosion and tensile strength.

Indeed, Alloy 20 has been manufactured to perform exceptionally well in manoeuvring highly corrosive acids such as sulfuric in chemical process industries.

Stainless steel valves are normally compatible with a range of working pressure of up to 200°C (392°F) although pressure allowance of different grades may differ.

Forged steel is superior to cast steel in terms of tensile strength and is less likely therefore to crack under high pressure or very high stress.

For 3-way ball valves, the pressure rating is depending on the material of body and balls and design can be up to Class 2500 or 6000 psi approximately.

Standard end reinforcements are threaded, flanged, socket welded, and butt-welded depending with the pipe specifications of the pipeline on hand.

Even the 3-way ball valves can only perform on/off control and switching between two flow pathways, but there are some types that offer flow control.

Trunnion-mounted valves offer more support to the ball and are preferable for applications where high pressure is involved, and large valves are used.

Types of actuators are: manual handles, pneumatic actuators, electric actuators and hydraulic actuators.

Connection type includes threaded, flanged and weld on installation aspect. Be sure to use recommended practices and make alignment correctly in order to avoid leaking.

Wear check up, cleaning of the ball and seal, and greasing of other moving parts should be done over and over in order to enhance productivity and durability.

Yes, most of the 3 way ball valves are made with ease of maintenance in mind, and can means that seals or the ball can be replaced without necessarily having to replace the whole valve.

Certain precautions must be taken before using it, for instance, look for signs of corrosion or dirt and apply suitable grease on such parts as can move since you must check and if necessary cycle the valve.

Signs that suggest that a certain actuator may need to be repaired or replaced include poor performance, and when it is hard to turn the actuator; leaks along the connections or where the valve is visible; apparent damage to the valve is also a sign.